Manfred Töller GmbH Expands its Product Range to Include 5-axis Machining

Manfred Töller GmbH, experts in the production and laser machining of signs, lettering, molded parts, and lighting made of acrylic glass and stainless steel, has successfully manufactured its first 5-axis components using their Pictures by PC CAD/CAM software from Munich-based SCHOTT SYSTEME GmbH.

Manfred Töller GmbH, experts in the production and laser machining of signs, lettering, molded parts, and lighting made of acrylic glass and stainless steel, has successfully manufactured its first 5-axis components using their Pictures by PC CAD/CAM software from Munich-based SCHOTT SYSTEME GmbH.

To expand its machining capabilities in the decoration and advertising sector, the company has acquired a large-format milling machine (4,200 x 1,200 x 900 mm) from CMS to utilize state-of-the-art 5-axis simultaneous milling processes. This includes, for example, the production of professional lettering for boats and yachts, as well as the custom manufacturing of exclusive decorative objects.

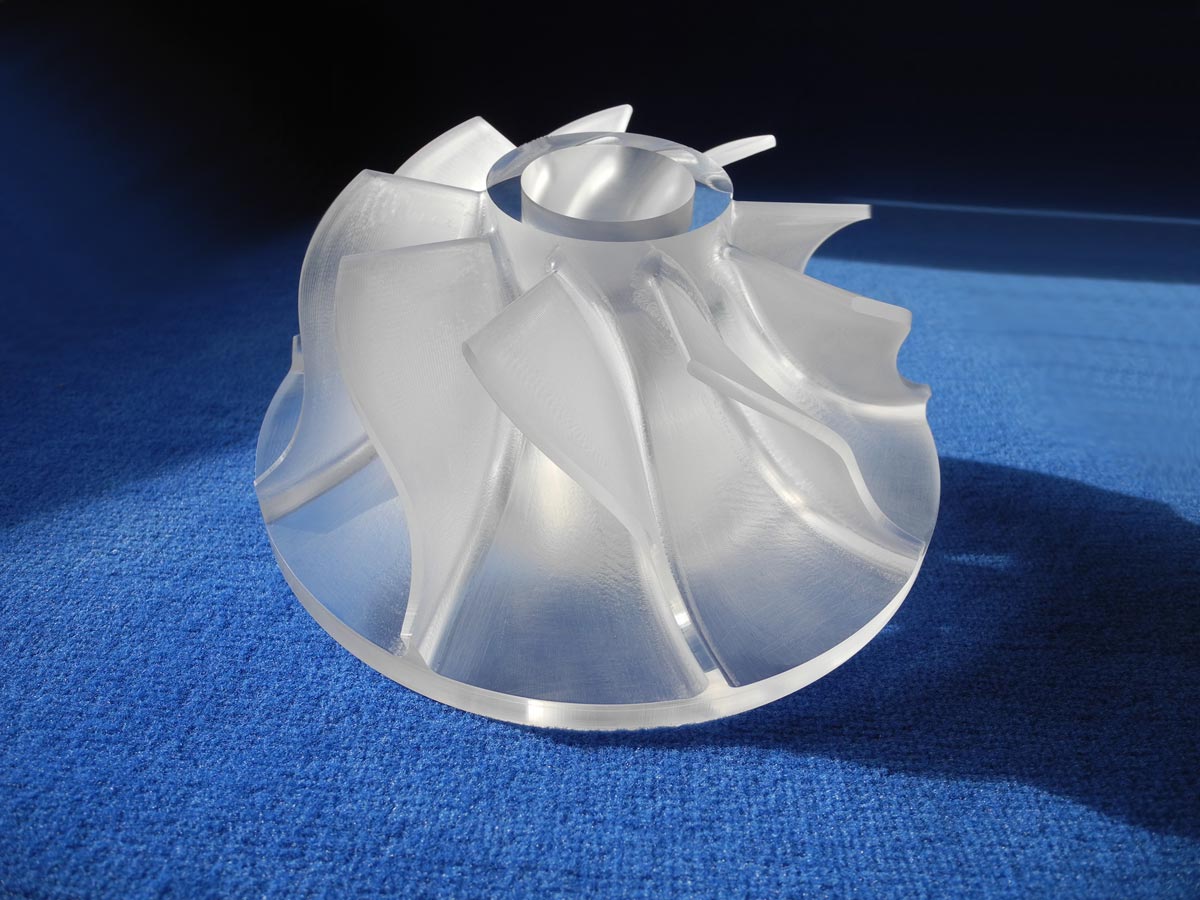

To initially test the advantages of this innovative technology, the company produced an impeller (Figure 1) from 100 mm thick Plexiglas® using a single machining setup. Following the successful trial run, the first customer components were produced. The part shown (Image 2) was milled from 40 mm thick acrylic glass and served as a prototype for the acrylic glass substructure of a yacht sign. Large, curved chamfered surfaces made it ideal for simultaneous 5-axis swarf and chamfer cutting using the CAD/CAM software Pictures by PC. This enabled significantly faster machining times and better surface finish quality than when using conventional 3-axis machining processes.

Töller was founded in 1946 and remains a family business, now in its third generation. Learn more about the company's high standards at www.laserkraft.de