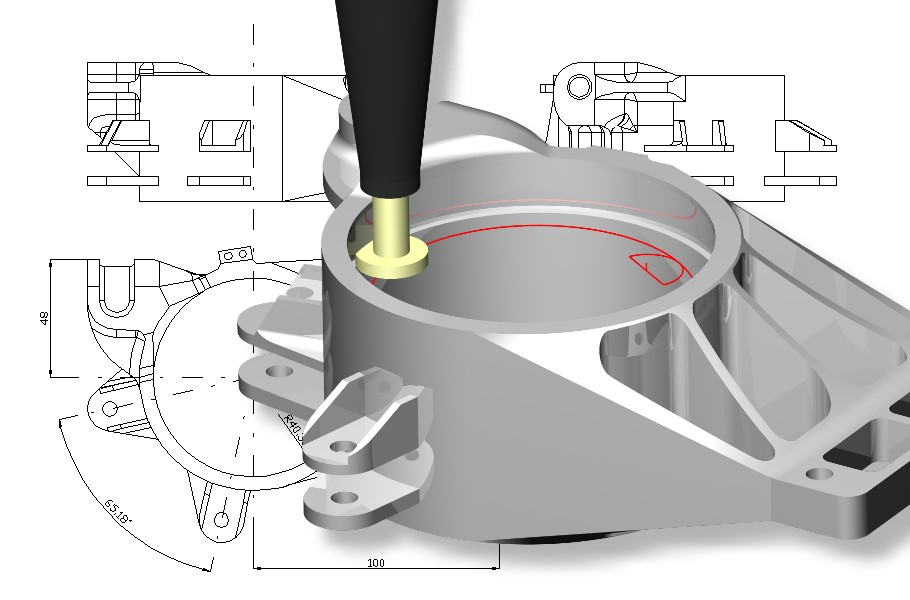

Pictures by PC CAM Software for 2.5D Milling and Drilling

2D/3D Milling, Drilling, Engraving

Pictures by PC enables the CNC milling, drilling and engraving of 2D and 3D CAD geometry within a few simple steps. Feature recognition extracts pocket and hole information directly from the CAD geometry. Proven machining strategies are applied with a single mouse click, and altered to suit. Toolpaths can be simulated (incl. stock material, tooling and clamping components), and translated into NC code using a machine post processor. NC worksheets are created to display required tooling and cutting times.

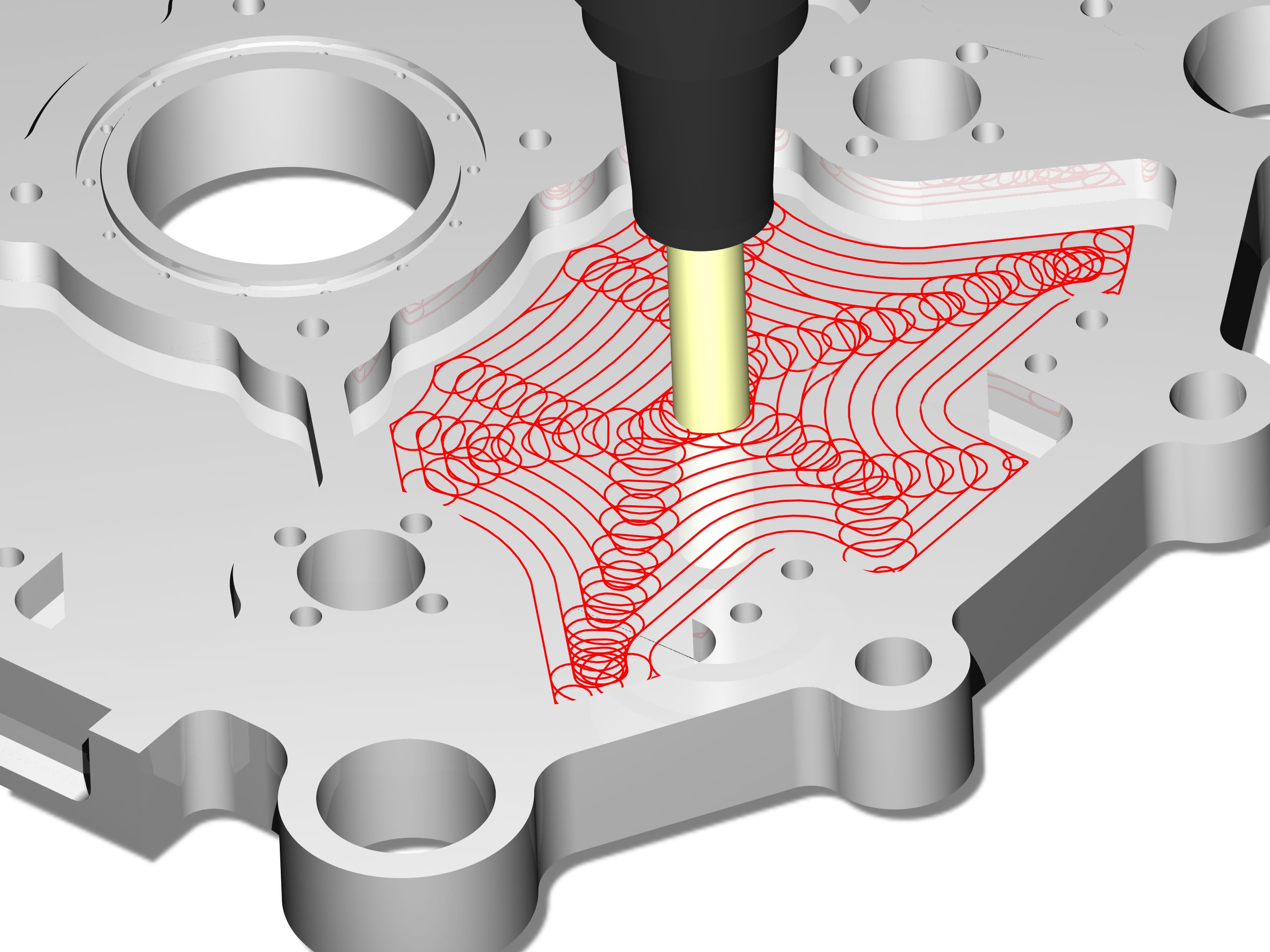

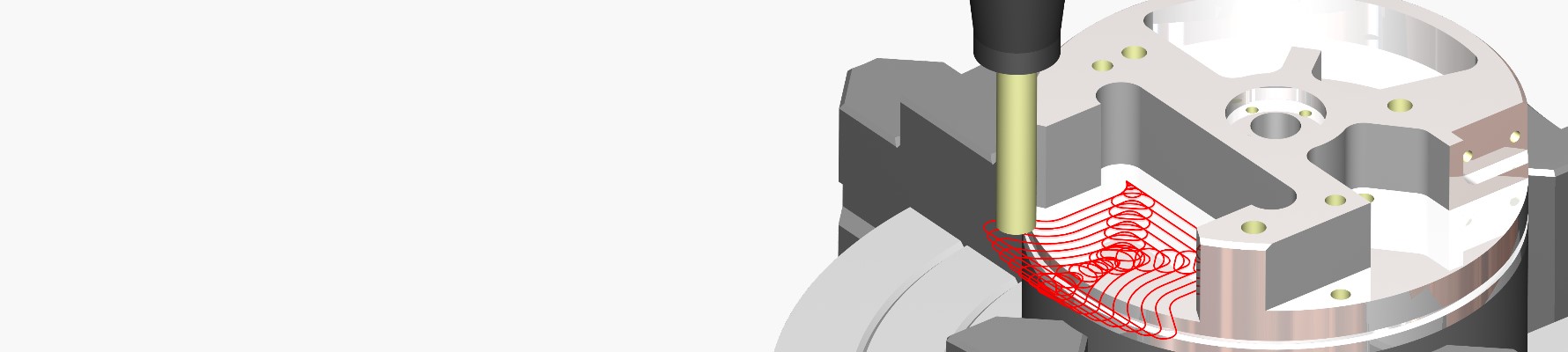

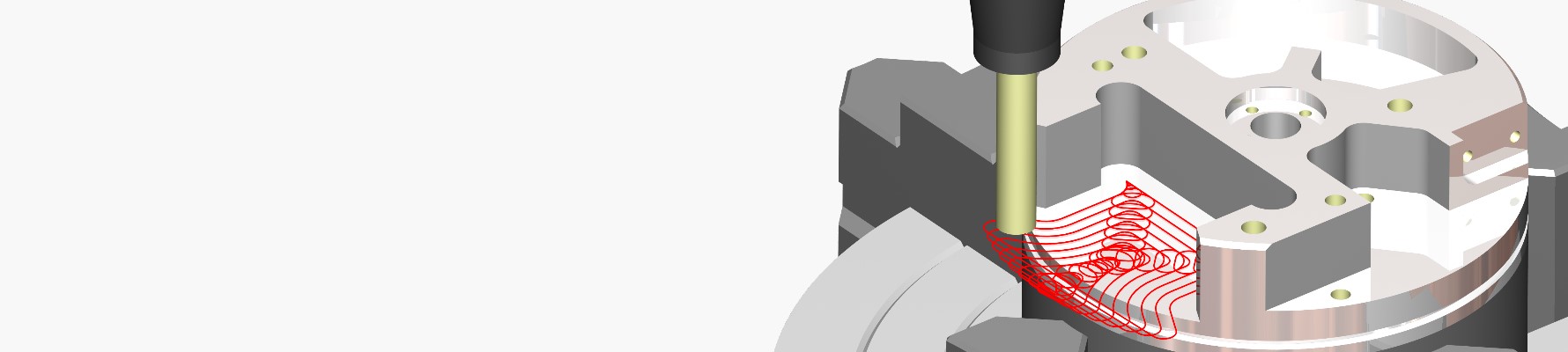

Trochoidal High Performance Cutting (HPC)

Trochoidal high performance cutting (HPC) generates spiral (helical) toolpaths that morph between differing pocket features (without tool retraction). This technique ensures constant cutter loads, enabling increased cutting depths and feeds to be used. Advantages also include less tool wear and improved surface finish. Feed rate compensation adjusts the feed rate according to the volume of material being milled. Optimal feed and speeds can be saved for differing machines and materials.

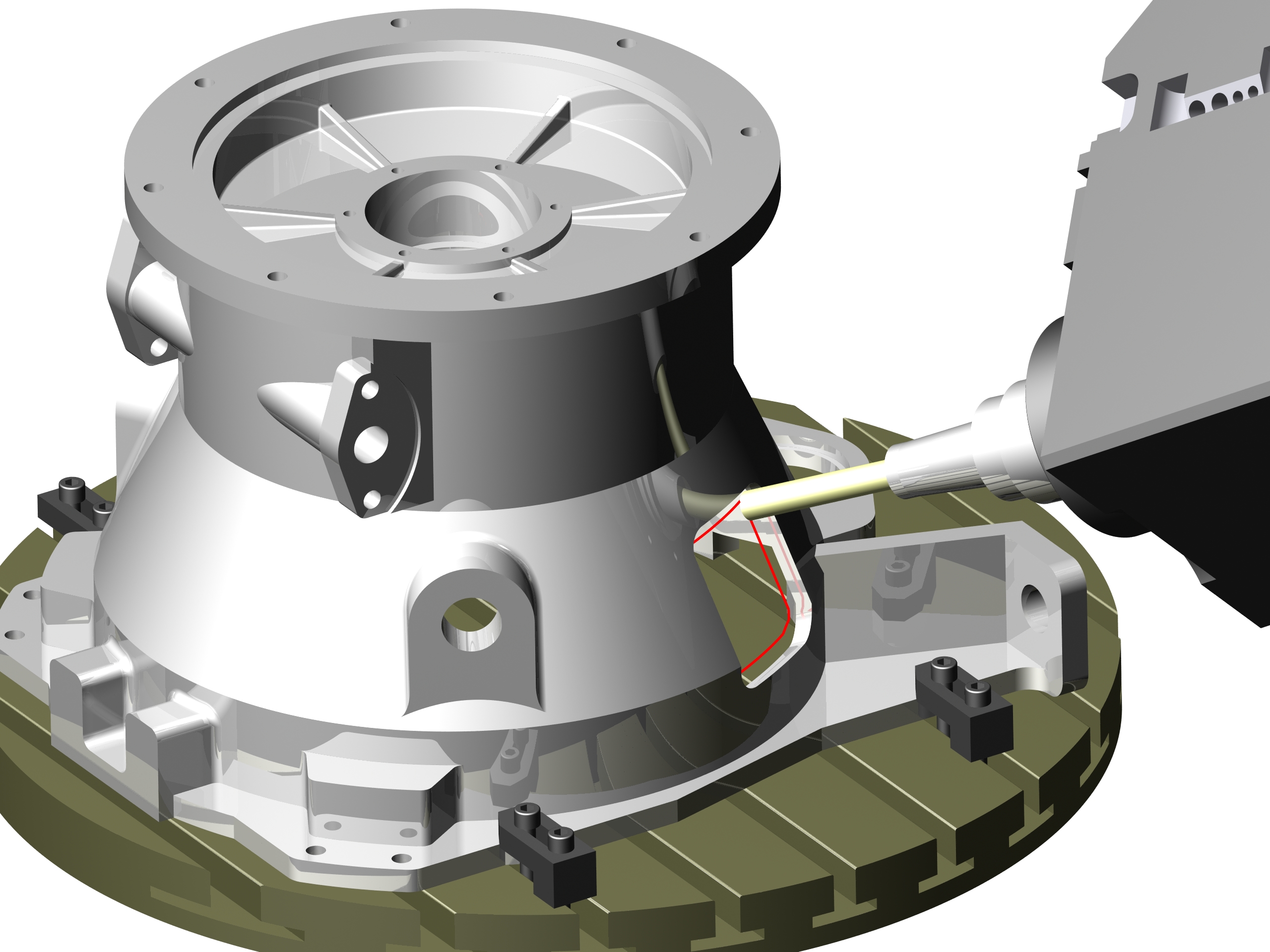

Multi Axis Machining (3+2)

Pictures by PC includes 4 axis rotary (3+1) and 5 axis (3+2) multi axis machining as standard. Feature recognition identifies pockets and holes from differing orientations. Both single or multiple (tombstone) components can be machined using a single setup. 5 axis post processors for standard controllers are included at no extra cost. 5 axis simultaneous machining is available as an additional module.