Pictures by PC CAM Software for 2 Axis Turning and Turn/Mill

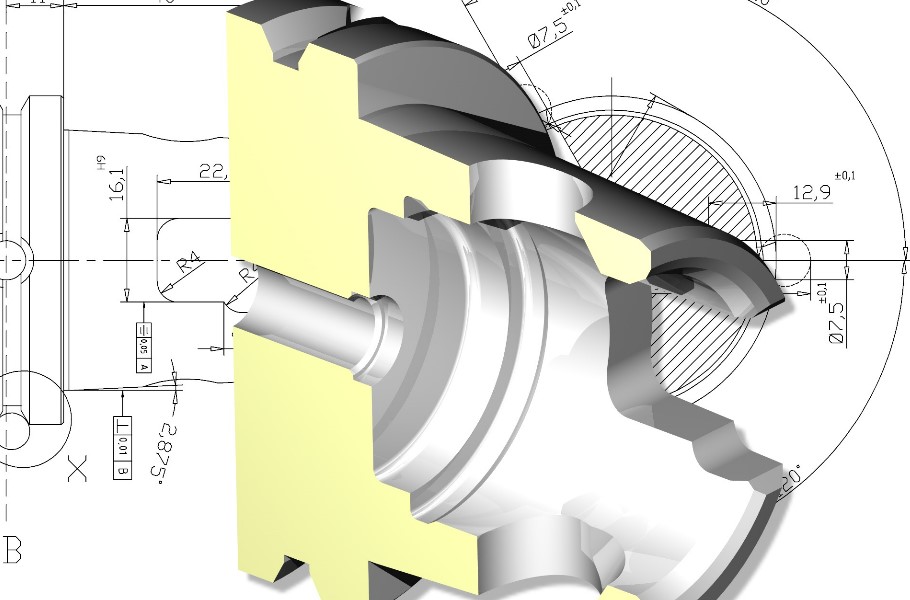

2-Axis Turning

Pictures by PC enables the 2 axis turning of CAD geometry. With just a few mouse clicks, proven machining strategies (roughing, finishing, grooving, threading, parting off and drilling) can be transferred to new turned parts. Toolpaths can be simulated (incl. stock material and clamping tooling) and translated into NC code using control-specific post processors.

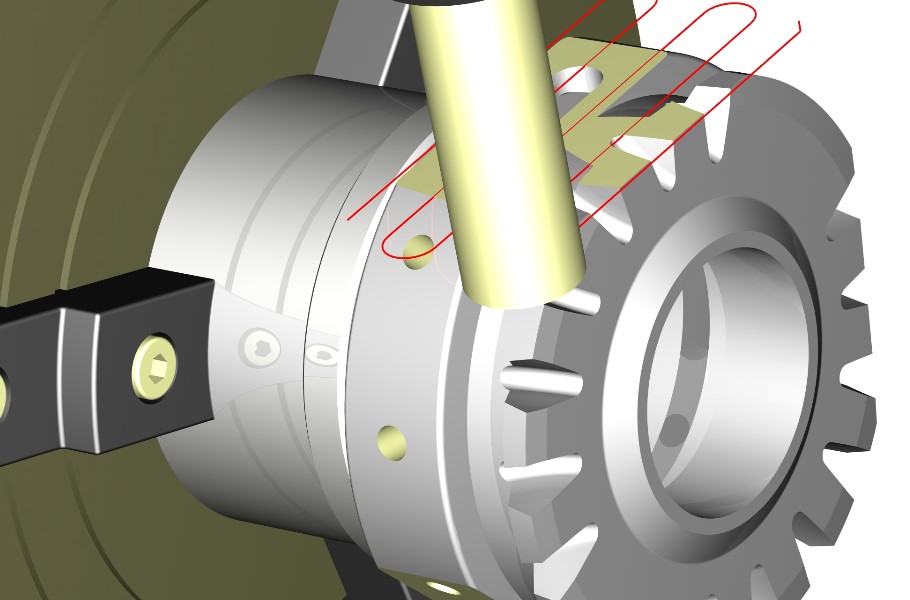

Multi-Axis Turn/Mill *

Turning with multi-axis and/or multi-spindle (C, Y and B axes). The turning and milling operations are located within a single, integrated user interface. This single programming environment enables the simulation and NC program generation of the combined milling, drilling and turning operations - * requires the 5 axis simultaneous module

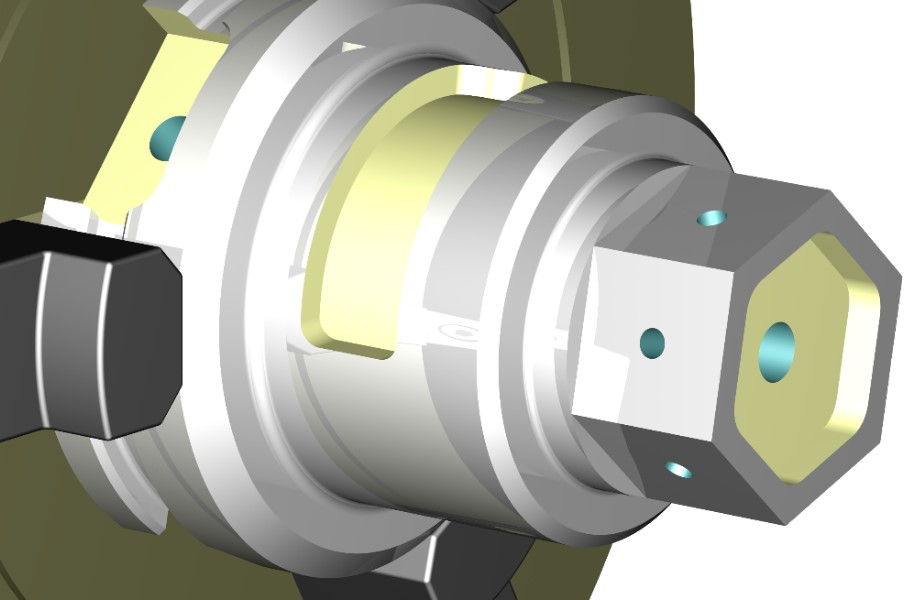

Feature Recognition and Live Stock Update

Feature recognition automatically identifies areas (pockets, turning contours and holes) that are to be cut directly from 2D and 3D CAD geometry. Live stock calculation updates stock material after each turning operation. This ensures that subsequent toolpaths are only calculated in areas that require further machining.