Pictures by PC CAM Software for Wire EDM Cutting

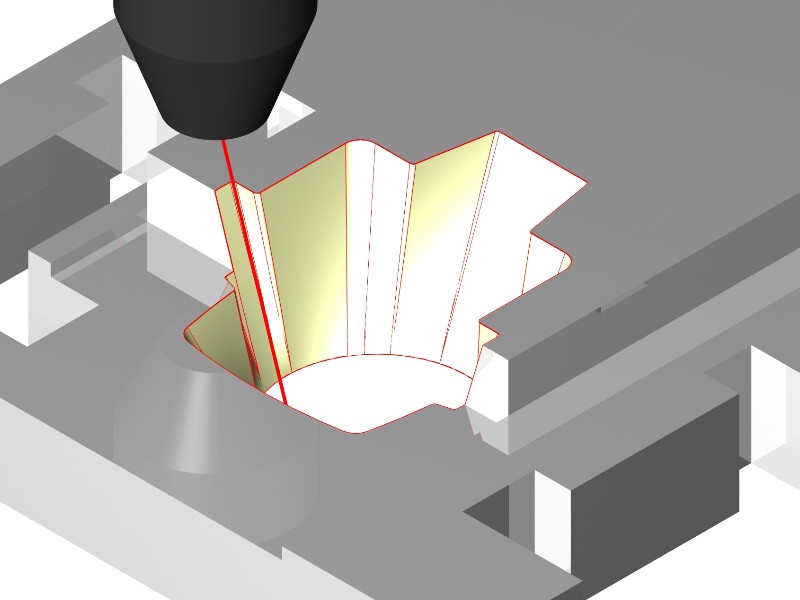

2 and 4 Axis Wire Cutting

Pictures by PC enables the CNC wire cutting of 2D and 3D CAD geometry in a few simple steps. Proven 2 and 4 axis machining strategies (roughing, finishing, destroy cutting) are applied with a single mouse click and adjusted accordingly. The user has full control over the cutting parameters. Corner types include ISO and conic corners. Toolpaths can be simulated with the machine post processor and translated into NC code.

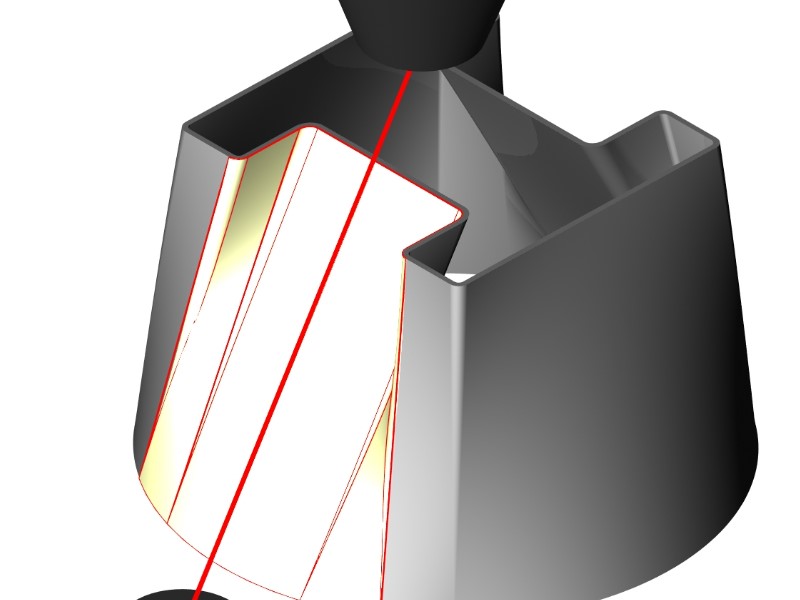

Manual and Automatic Wire Synchronisation

When cutting differing upper and lower contours, the software automatically synchronises the wire between the two contours (4 axis simultaneous cutting). The placement of vector direction symbols also enable the wire inclination to be manually adjusted at strategic points on the contours. The final sequence of cuts can be optimised across multiple operations, controlling the order of roughing, finishing and tag removal cuts.

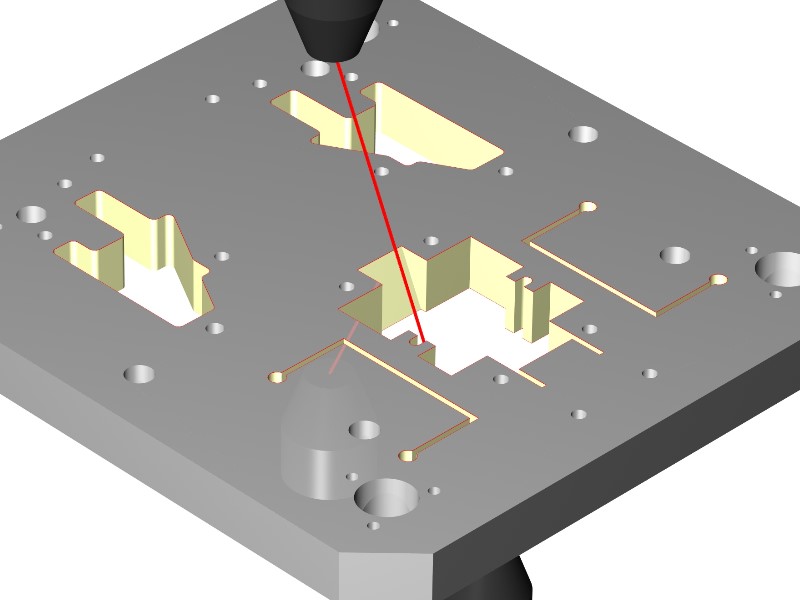

Feature Recognition

Feature recognition automatically identifies areas (pocket and hole contours) that are to be cut directly from 2D and 3D CAD geometry. Additional highlights include the automatic generation of involute gears for cutting and the full integration of all CAD tools for creating, changing and repairing 2D contours and 3D solid models.