Pictures by PC CAM Software for Engraving and Carving

Vector Graphic and Typography

New artwork can be sketched using the vector graphic design tools (Bezier, Nurbs). Typesetting tools (Truetype Postscript) offer the highest level of typography (Kerning, Editing, Unicode). Vector based artwork can be imported using Adobe Illustrator (AI), Encapsulated Postscript (EPS), Window Meta Format (WMF) and Enhanced Meta Format (EMF). Black and white bitmaps (scans) can be vectorised to generate engraving contours. Grey scaled photos can be converted into 3D mesh relief models.

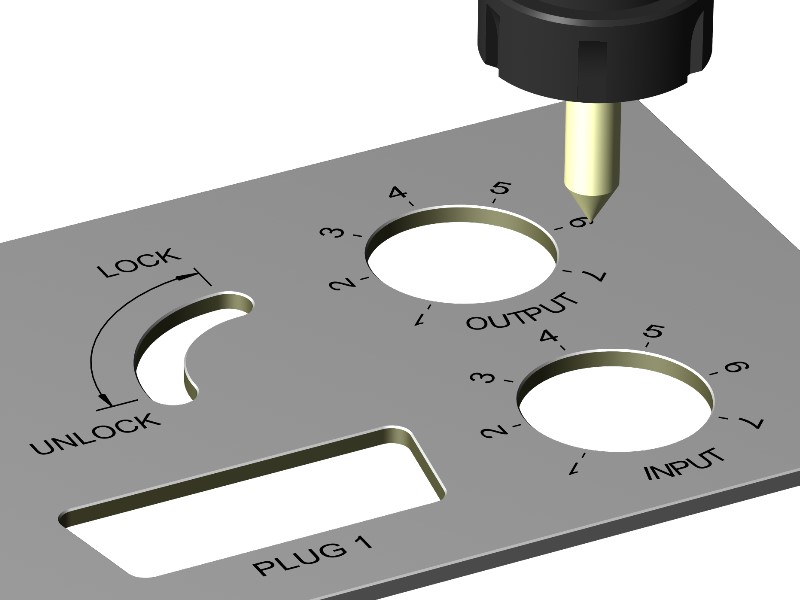

Engraving and Carving

Engraving involves running a tool with a constant depth of cut along the center of a contour. The tool diameter determines the width of cut. Carving requires a conical tool, and facilitates the cutting of sharp embossing stamps and imprints. To achieve this in a sharp corner of a contour, and corresponding to the conical angle of the engraving tool, a 3D toolpath is created to ensure the smallest conical radius is maintained at the top contour, leaving a "sharp" corner. Carving facilitates the production of both raised and indented stamps.

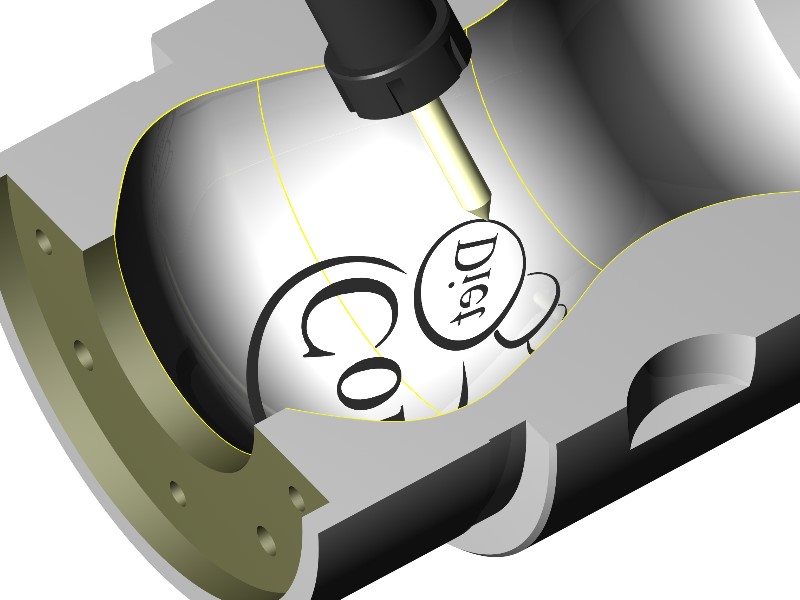

3D Projection and 3D Wrapping

2D engraving and carving strategies can be projected onto 3D solid, surface or mesh models. Toolpaths can also be wrapped around cylindrical, spherical or conical forms (simple curved surfaces). For more complex shapes (jewellery and woodworking) the simple curved toolpaths can be wrapped a second time around additional cylindrical, spherical or conical forms (double curvature surfaces). The resulting tool paths can be machined up to 5 axis simultaneously.