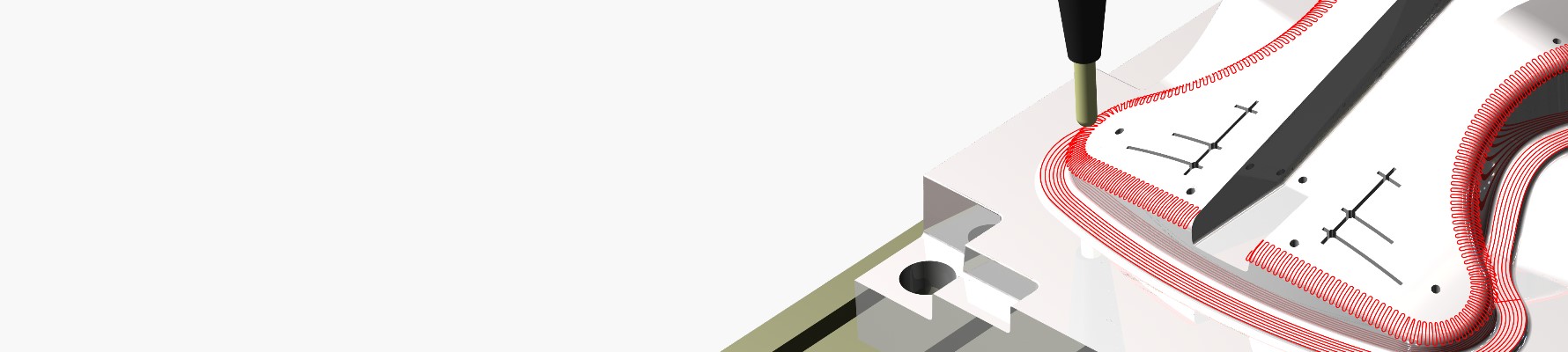

Pictures by PC CAM Software for 3D Freeform Machining

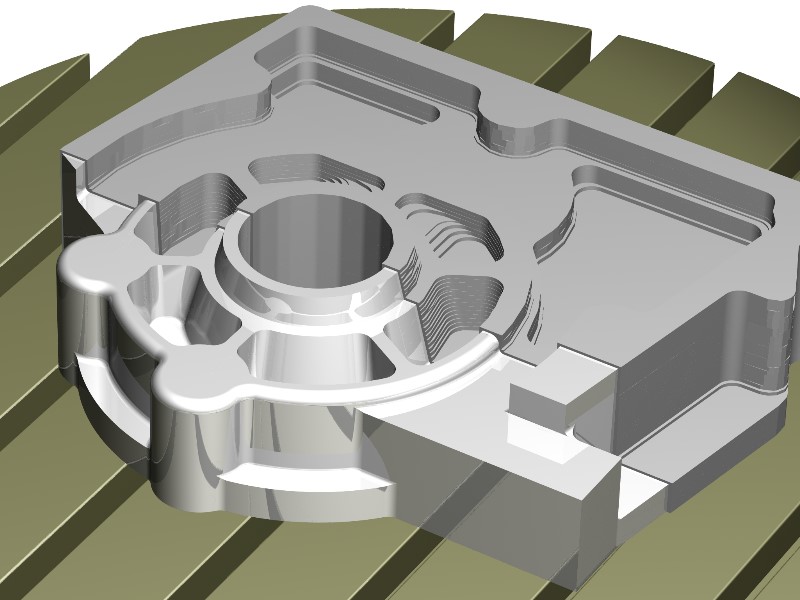

3D Freeform Machining (Roughing, Finishing)

Pictures by PC enables the 3D rough and finish machining of freeform models (solids, surfaces and meshes). Proven machining strategies are applied with a single mouse click, and altered to suit. Toolpaths can be simulated (incl. stock material, tooling and clamping components), and translated into NC code using a machine post processor. NC worksheets are created to display required tooling and cutting times.

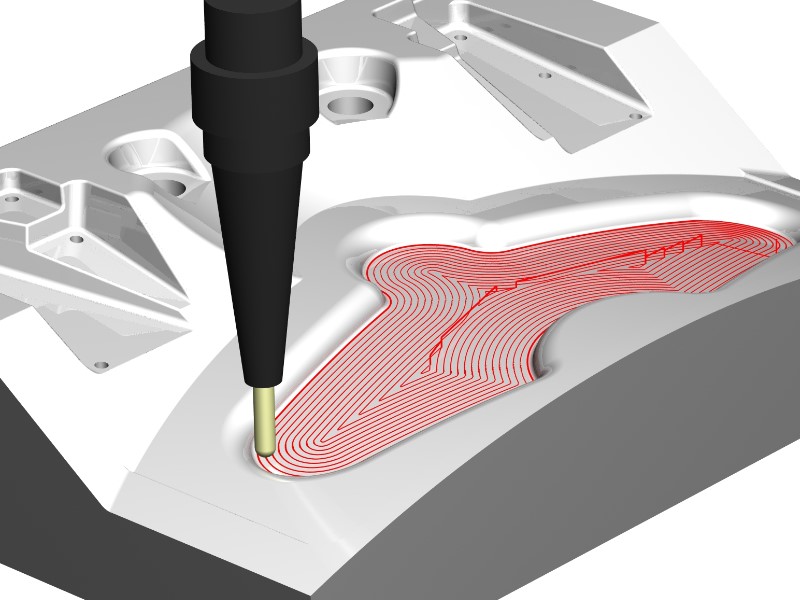

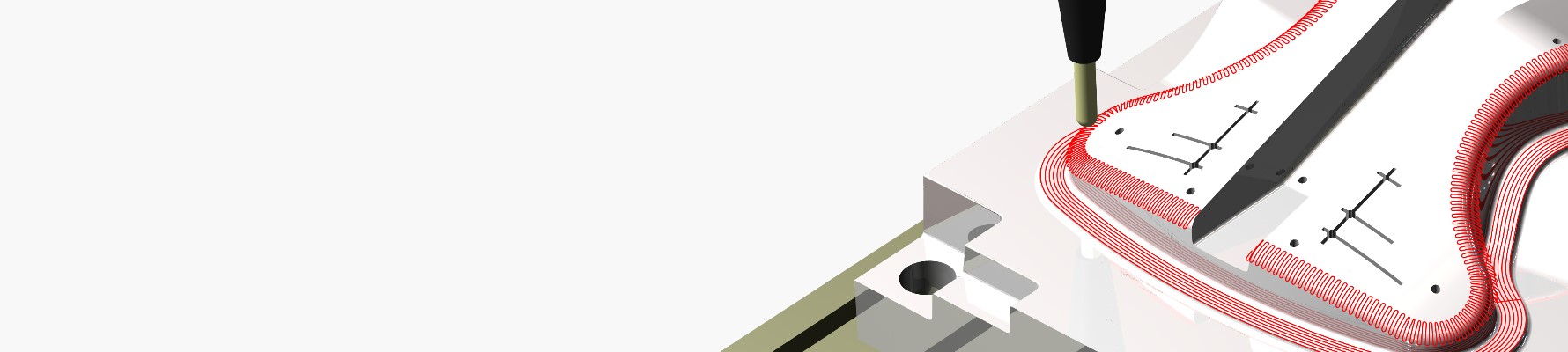

Trochoidal High Performance Cutting (HPC) - High Speed Cutting (HSC)

High speed cutting (HSC) increases the removal rate of material by utilising higher feeds, speeds and tangential toolpath connections.Typical finishing strategies include contour orientated, spiral or hybrid machining. The later is ideal for reducing programming times, by generating toolpaths to match both steep and flat areas on the geometry within a single operation.

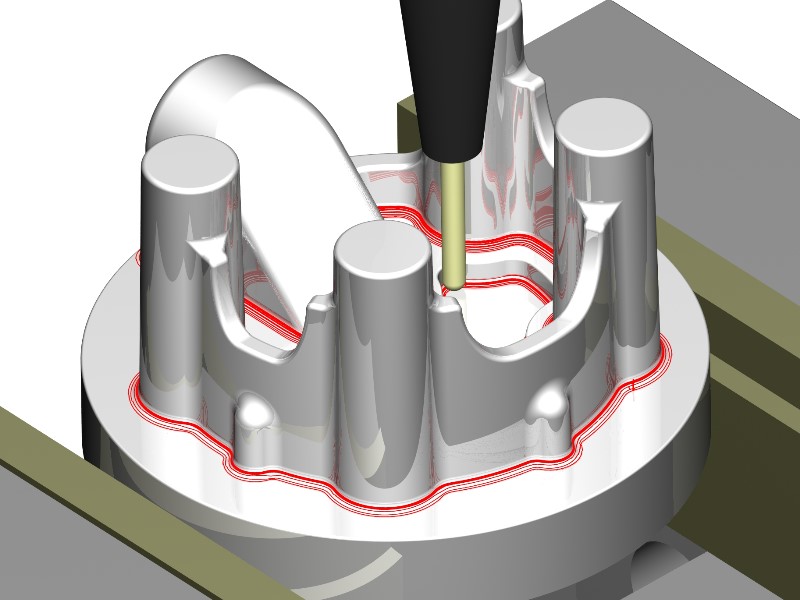

Topology and Rest Material Recognition

Feature recognition identifies areas of freeform 3D CAD geometry to machine (plane and tapered faces, chained radii, freeform pockets). Rest material recognition highlights areas that require re-machining after finishing operations. Automatic bounding contours contain the rest material machining. Support for multi-threading toolpath calculation ensures short calculation times of complex components on rudimentary hardware.