From the 3D CAD Model to Workpiece with Just One Click

At the EMO 2023 (Hannover, September 18-23, 2023), the German software manufacturer SCHOTT SYSTEME GmbH is offering visitors the opportunity to test its automated CNC processing CAMsmart live at the exhibition stand (Hall 9, Stand E05).

At the EMO 2023 (Hannover, September 18-23, 2023), the German software manufacturer SCHOTT SYSTEME GmbH is offering visitors the opportunity to test its automated CNC processing CAMsmart live at the exhibition stand (Hall 9, Stand E05).

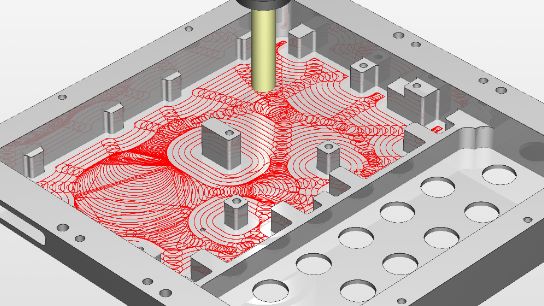

The brand-new automated drilling and milling with CAMsmart is a special focus of the latest version 3.10 of the CAD/CAM software Pictures by PC from SCHOTT SYSTEME GmbH. CAMsmart drastically reduces the CAM preparation times of typical multi-sided, prismatic workpieces (at least by a factor of 10) compared to previous procedures.

Visitors to the EMO 2023 are cordially invited to the booth of SCHOTT SYSTEME GmbH to have their own prismatic 3D models in STEP format tested live at the booth. The aim is not only to highlight the significant cost savings that are possible with such automation, but also to offer visitors a realistic benchmark so that they can practically compare the effectiveness of other CAD/CAM systems on the same models.

First, the CAMsmart process automatically aligns the 3D CAD model so that it is suitably orientated for the NC machine. This is followed by the geometric analysis of the workpiece, in which typical, multi-sided 2.5D or 3D milling and drilling features are identified. Tested machining strategies are then automatically assigned to the part according to criteria such as pocket size, corner radii, drill hole types and material (e.g., facing, contouring, pocket milling, chamfering, drilling, rounding and cornering). All strategies can of course optionally be edited. At the end of the automated process, there is also a simulation of the material removal and a check for possible collisions and rest material.

With its in-house developed software solutions, SCHOTT SYSTEME GmbH can refer to almost 40 years of product continuity. To date, no maintenance or support costs are charged for the software.

The proven Schott-Systems motto applies: Software benefits instead of software costs.

EMO 2023 - Hall 9 Stand E05

www.schott-systeme.de