SCHOTT SYSTEME GmbH Presents Fully Automated Machining at the INTEC 2023

February 2022 - On the INTEC 2023 (Leipzig, March 7th to 10th March, 2023), German software manufacturer SCHOTT SYSTEME GmbH are to demonstrate the significant performance enhancements of version 3.10 of their Pictures by PC-CAD/CAM software.

February 2022 - On the INTEC 2023 (Leipzig, March 7th to 10th March, 2023), German software manufacturer SCHOTT SYSTEME GmbH are to demonstrate the significant performance enhancements of version 3.10 of their Pictures by PC-CAD/CAM software.

This latest release builds on almost 40 years of software development by SCHOTT SYSTEME GmbH, with their universal Pictures by PC CAD/CAM Software (priced at under 10,000€) offering a cost-effective solution for all aspects of design and machining, from precision machining and machine design through to mould tool design and rapid prototyping. With SCHOTT SYSTEME’s focus on ‘Software Use Instead of Software Costs’, this release sees the company continuing their policy of not charging for yearly maintenance, while including machine post processors for all standard controllers free of charge.

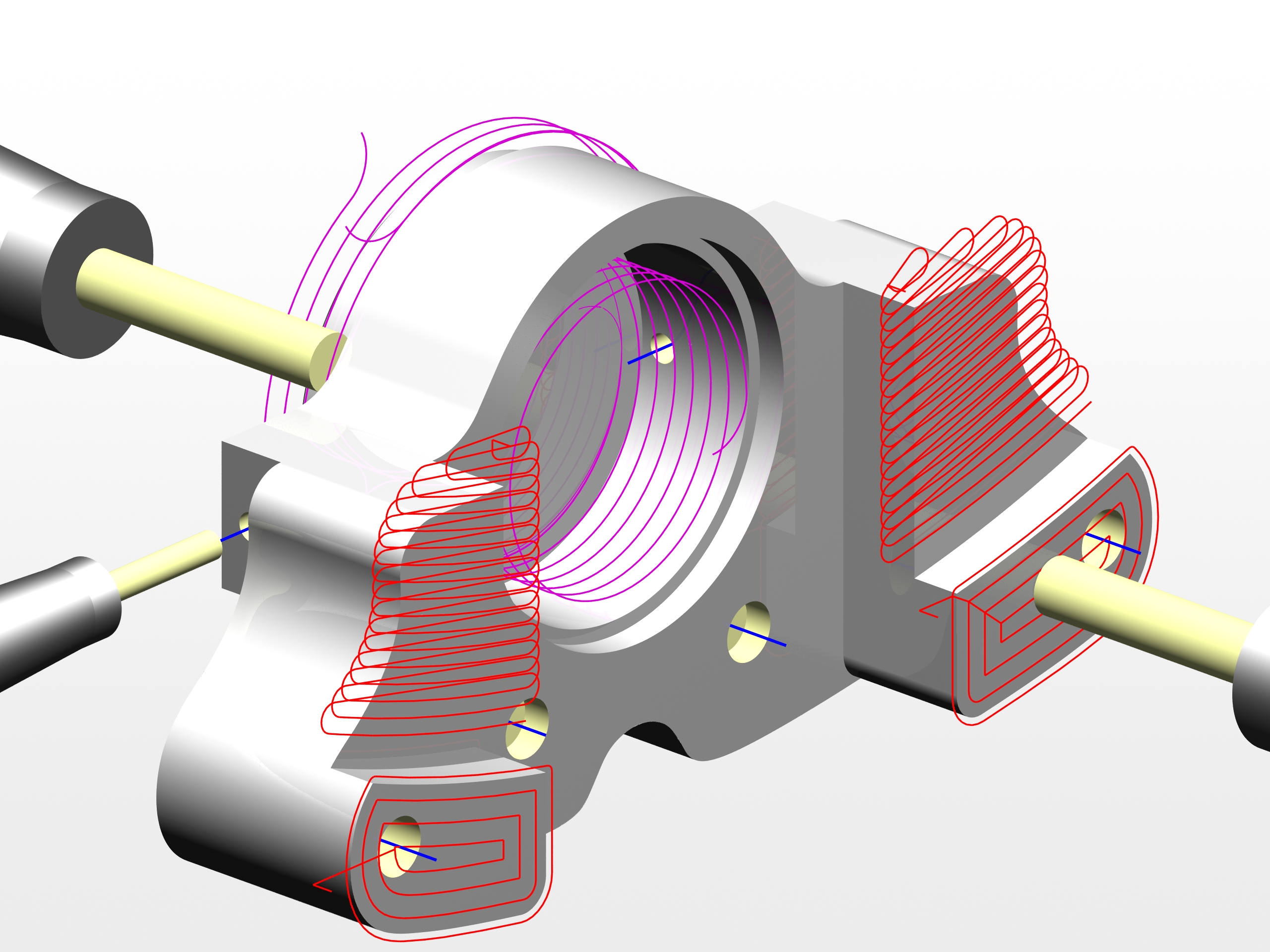

CAMSmart Automated Milling - Version 3.10 automates the processing of machining for multi-sided prismatic workpieces. Working on constructed or imported 3D CAD volume models (usually via STEP or IGES, VEC and VCZ), the part geometry is analysed for typical, multi-sided 2.5D or 3D milling and drilling features. Appropriate machining operations are then automatically applied to the part (e.g., facing, contouring, pocket milling, chamfering, drilling, edge rounding), relating to customisable criteria such as material, pocket size, corner radii and hole types. The software also facilitates transferring the machining almost instantly to differing machines with differing axis configurations. INTEC visitors are invited to bring along typical 3D prismatic parts as STEP files in order to test them live at the SCHOTT SYSTEME booth.

Other noteworthy CAM features include user-defined tool shapes (e.g. parabolic cutters, barrel cutters, concave radius cutters, etc.) that can be defined using a 2D sketch (e.g. DXF) and used on 3- to 5-axis milling machines. 5 axis cutting out of thermoformed components facilitates differing offsets and cutting depths around the part. The milling of plate material is enhanced with contour machining and the inclusion of tags with manual or automatic placement. The machining of undercut regions is also supported through the use of lollipop and plate milling cutters.

Hybrid Modelling and Construction - Pictures by PC’s Version 3.10 2D CAD and hybrid 3D Modeller (Solid, Surface, Mesh) also includes numerous improvements for 2023, all of which can be seen, in addition to the new CAM features, live on the INTEC exhibition in Leipzig from 7th to 10th March.

Visit SCHOTT SYSTEME GmbH in Hall 2 on Stand A15