Innovation and Flexibility in Bespoke Machine Design

Stöckl Sondermaschinenbau GmbH continues to be at the forefront of technological innovation in bespoke machine construction and automation.

Stöckl Sondermaschinenbau GmbH continues to be at the forefront of technological innovation in bespoke machine construction and automation.

Based in Königsdorf - south of Munich, the company has been innovating in bespoke machine design since 1984. The family run business, originally founded by Georg Stöckl, and now jointly run with his son Markus Stöckl, continues to be at the forefront of technological innovation in special machine construction and automation, with a cross-sector technology spectrum for a wide variety of application areas. The company is also a networked supplier to the automotive industry for automated press lamination and folding systems as well as attachment devices for manual lamination, folding and prefixing of decorative seams, especially in the real leather sector. The company Stöckl Sondermaschinenbau GmbH is certified according to ISO 9001: 2015.

Integrated CAD/CAM Software from Germany

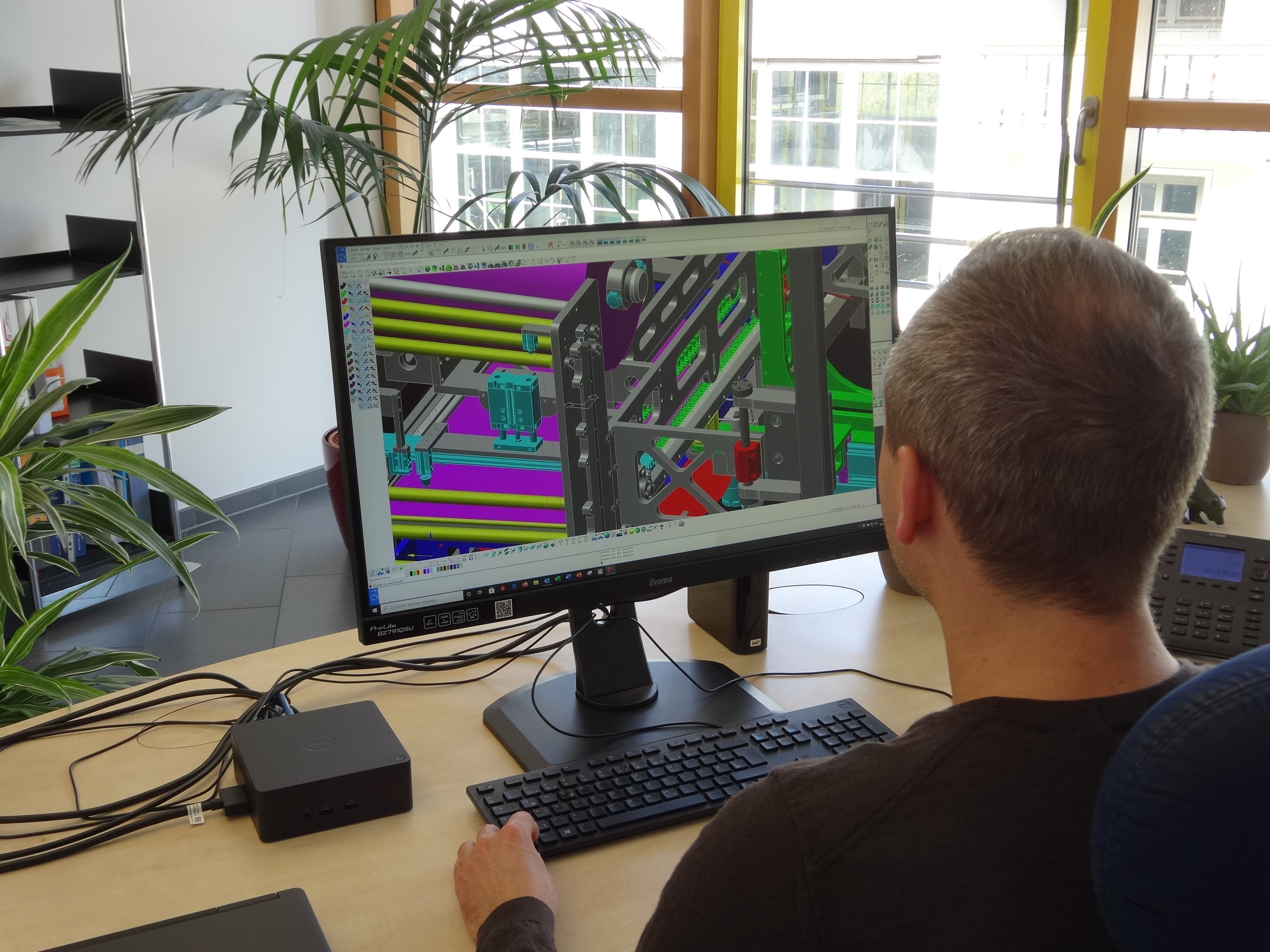

To aid in their design process, Stöckl Sondermaschinenbau GmbH had previously invested in a market leading parametric CAD system back in 1999. The company however decided in 2015 to search for a more flexible design solution that included full CAM machining capabilities, from a German CAD/CAM software developer. The software had to include 2D CAD for initial concept layout design, 3D mechanical and freeform modelling, as well as the ability to easily handle extremely large 3D assemblies within a standard hardware environment. To power their 4 axis DMC 1150V milling machine, the software should also include 2.5D prismatic milling, 3D HPC (High Performance Cutting) and HSC (High Speed Cutting) freeform machining, as well as 5 axis prepositional milling and drilling as standard. This search led them to purchase Pictures by PC CAD/CAM software developed by Munich based SCHOTT SYSTEME GmbH.

Design Complexity

Bespoke machine design requires companies such as Stöckl Sondermaschinenbau GmbH to be master of many different disciplines, including mechanical construction and ergonomic design, as well as pneumatic and electrical layout of systems. With no one machine design being the same, CEO Markus Stöckl states “Our main motivation is that we are continually faced with technical challenges for which there is no standard solution.”

Bespoke machine design requires companies such as Stöckl Sondermaschinenbau GmbH to be master of many different disciplines, including mechanical construction and ergonomic design, as well as pneumatic and electrical layout of systems. With no one machine design being the same, CEO Markus Stöckl states “Our main motivation is that we are continually faced with technical challenges for which there is no standard solution.”

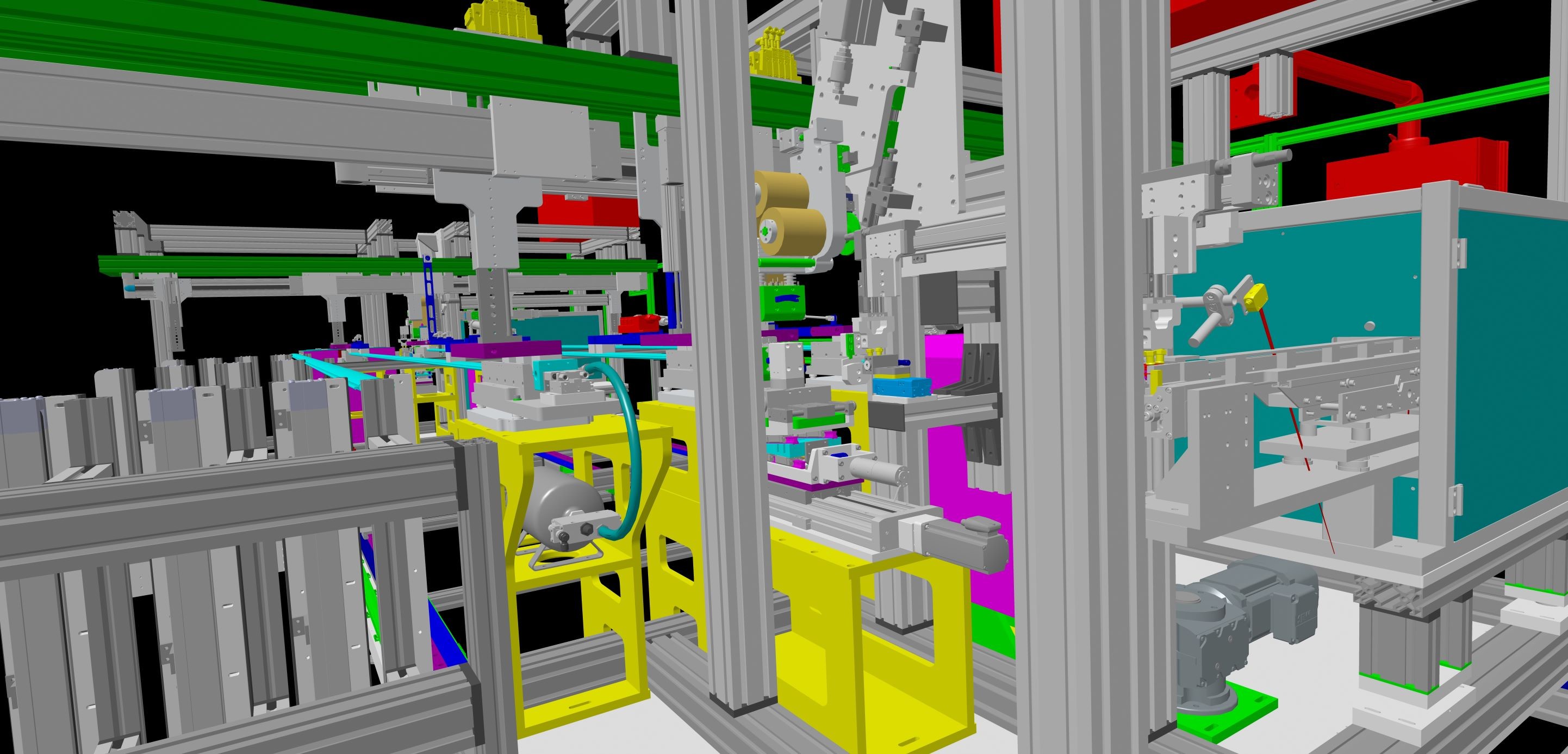

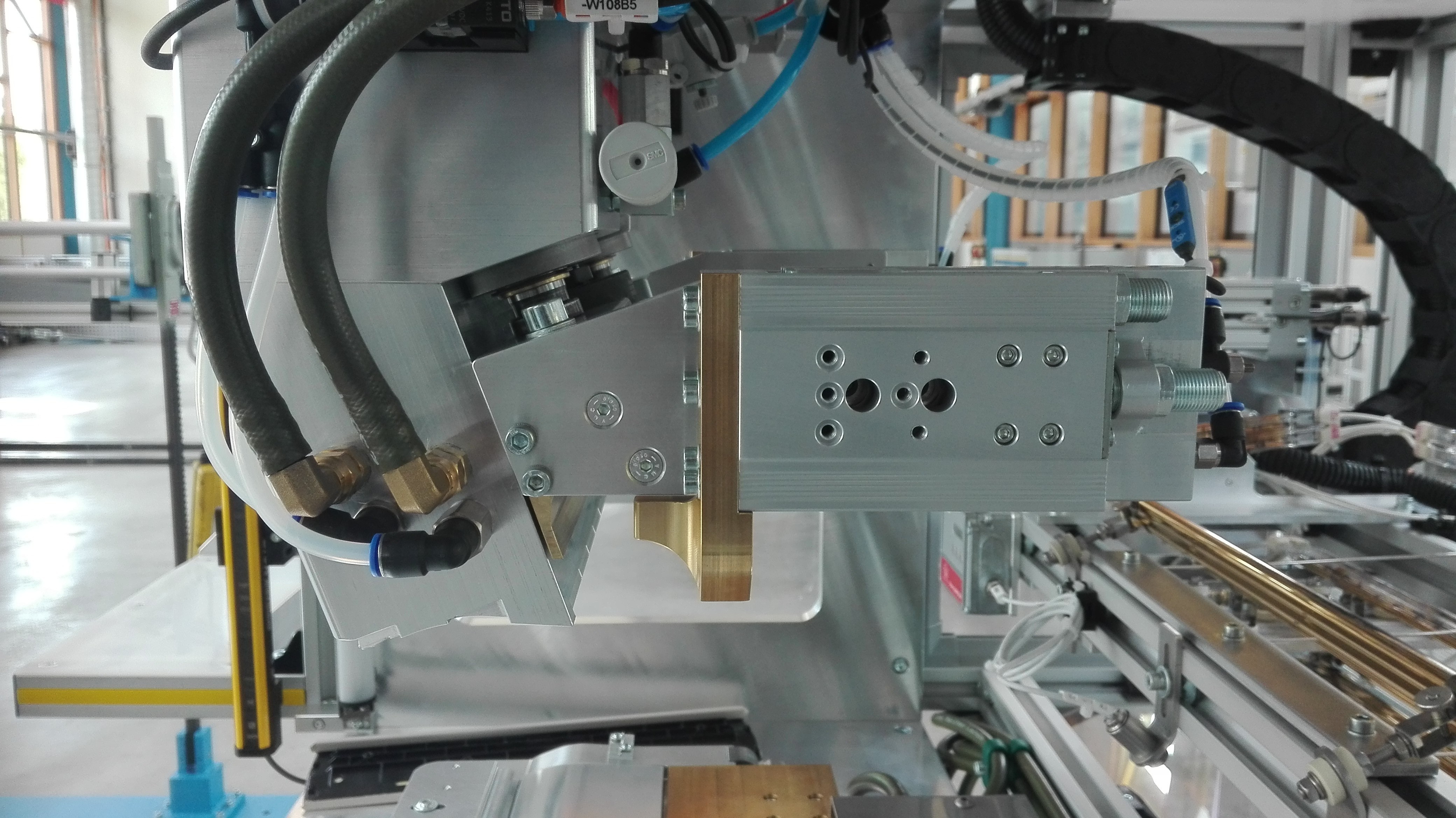

It is not unusual for the company to receive requests for fully automated systems that run across multiple stations, undertaking a range of differing production and assembly tasks. Markus Stöckl cites a recent machine for Rollo Solar Melichar GmbH, a market leader in premium swimming pool covers - “The system had to automatically carry out all production steps of the pool cover machines across multiple stations, including cutting of the decking profiles, subsequent cleaning of the profiles, automatic feeding and thermal welding of the end caps, in addition to precise contour milling of the weld seam protrusions”.

The resulting 3D CAD model, designed completely using their Pictures by PC software, consisted of over 45,000 components, the vast majority of which are bespoke including sheet metal parts. These were modelled using Pictures by PC’s direct modelling tools, whereby 3D CAD models can be interactively altered without the need for a complex parametric feature tree, as was required with their previous CAD solution. Markus Stöckl estimates this new modelling approach alone led to a 60% time saving during the design phase over their previous modelling methods - “With Pictures we have a software with which we can very quickly transfer our first thoughts into preliminary concepts and then into detailed constructions. During the entire design phase, we now have the necessary flexibility to quickly and easily make changes and adjustments, even to complex assemblies, without having to worry about which components are linked with which dependencies - as would be the case with parametric systems. “

Design and Production Under One Roof

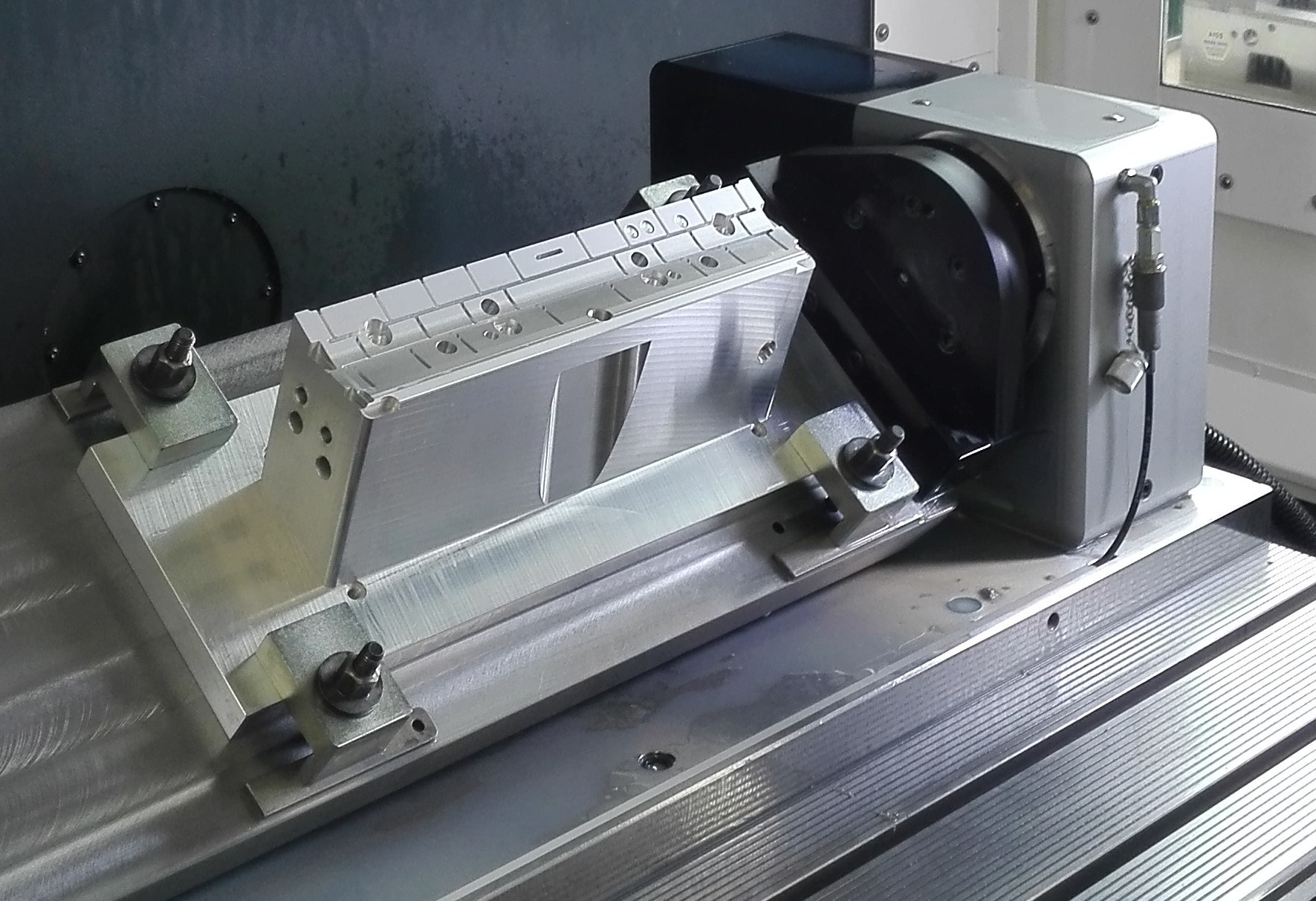

Just as diverse as their designs, Stöckl Sondermaschinenbau GmbH has very diverse machining requirements, from typical prismatic milling of machinery components, to the complex 3D machining of their laminating and folding tools, with the later not being possible when programming directly on their Heidenhain 640 controller. Markus Stöckl elaborates “With our Pictures by PC CAD/CAM software, we can both design and manufacture the entire range of components required for our systems, from simple contour milled parts, to general fixture and mechanical components, to 3D freeform tools with more complex geometry.”

Just as diverse as their designs, Stöckl Sondermaschinenbau GmbH has very diverse machining requirements, from typical prismatic milling of machinery components, to the complex 3D machining of their laminating and folding tools, with the later not being possible when programming directly on their Heidenhain 640 controller. Markus Stöckl elaborates “With our Pictures by PC CAD/CAM software, we can both design and manufacture the entire range of components required for our systems, from simple contour milled parts, to general fixture and mechanical components, to 3D freeform tools with more complex geometry.”

Since purchasing SCHOTT SYSTEME’s in-house developed CAM software, the company has identified numerous areas where they have witnessed noticeable gains over their existing machining methods. These include higher-quality finishing of freeform surfaces on form components using Pictures by PC’s 3D HSC (High Speed Cutting) operations such as Spiral Finishing, higher accuracy of tolerances on milled components (producing time savings during assembly), milling of ready to fit components that do not require subsequent deburring, and a general decrease in programming and milling times, estimated by Markus Stöckl at being an approximate saving of 75% over their existing programming methods.

Remaining at the Forefront of Innovation

The landscape of special machine design changes on a daily basis for Stöckl Sondermaschinenbau GmbH. Having previously focussed more heavily on the automotive industry, the company is now branching out into more diverse areas such as the food industry. A desire to constantly innovate also sees them involved in numerous research projects including collaboration with Ludwig Maximilians University of Munich (Acceleration system - Biomechanics department) and the Chemnitz University of Technology (System for processing fibre plant stems for construction materials - Competence center for lightweight structural engineering).

The landscape of special machine design changes on a daily basis for Stöckl Sondermaschinenbau GmbH. Having previously focussed more heavily on the automotive industry, the company is now branching out into more diverse areas such as the food industry. A desire to constantly innovate also sees them involved in numerous research projects including collaboration with Ludwig Maximilians University of Munich (Acceleration system - Biomechanics department) and the Chemnitz University of Technology (System for processing fibre plant stems for construction materials - Competence center for lightweight structural engineering).

When summing up these new challenges and their cooperation with SCHOTT SYSTEME GmbH, Markus Stöckl simply answers “The need for bespoke machine solutions is increasing, but as almost every machine is unique and the development periods are getting shorter and shorter, we need high-performance software with high flexibility, at the same time with the best possible support. In SCHOTT SYSTEME we have found a reliable partner. Pictures by PC has been continuously developed in Germany, since over 35 years, and thanks to their computer-based licensing we have full cost control and absolute data sovereignty, which is an important factor for our company.”