SCHOTT SYSTEME Reduce 5 Axis Milling Times

German software developer SCHOTT SYSTEME GmbH is reducing 5 axis simultaneous toolpath calculation times of complex workpieces through the use of Interactive Direction Vectors within their Pictures by PC CAD / CAM Software.

German software developer SCHOTT SYSTEME GmbH is reducing 5 axis simultaneous toolpath calculation times of complex workpieces through the use of Interactive Direction Vectors within their Pictures by PC CAD / CAM Software.

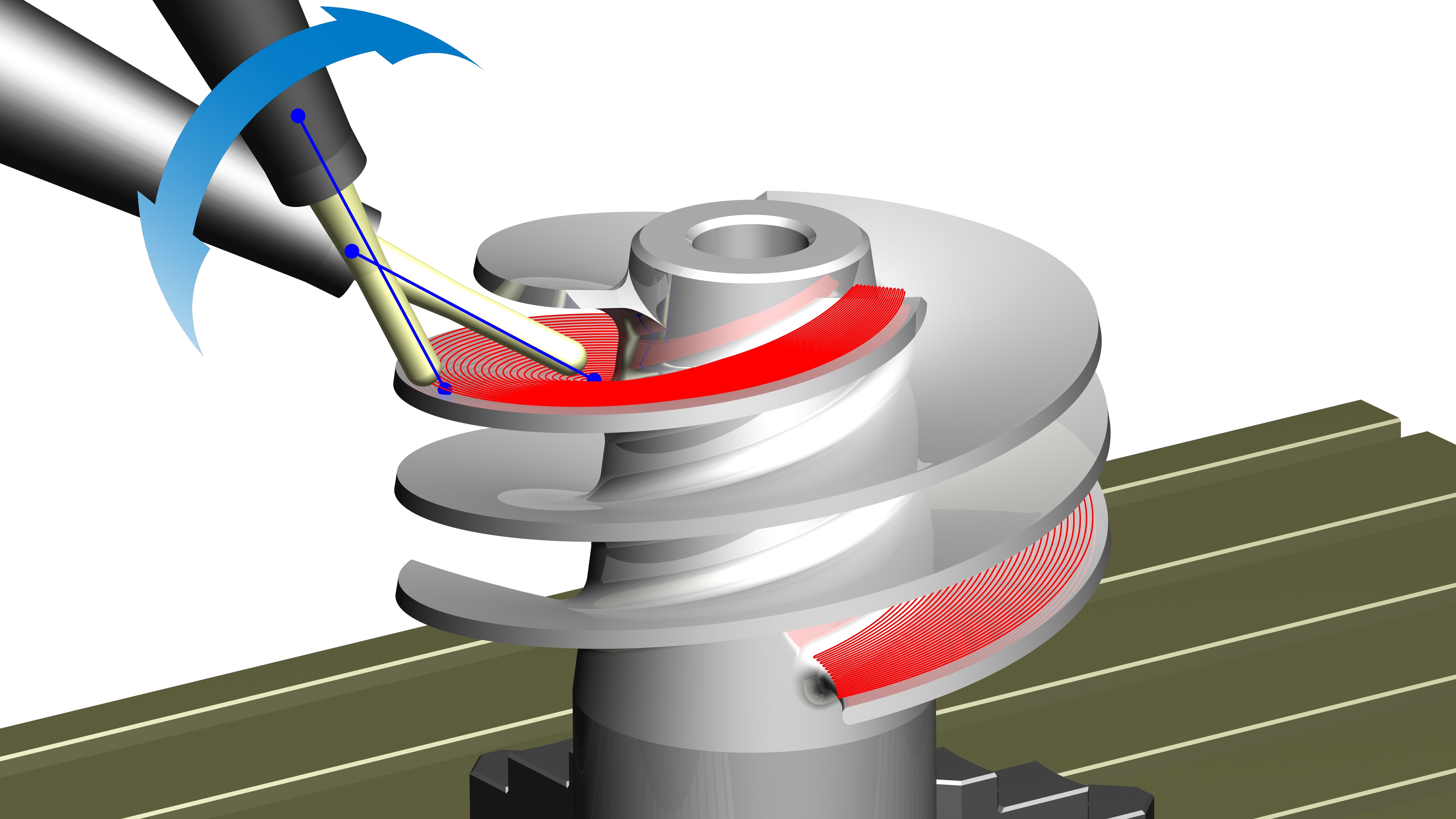

Interactive Direction Vectors can be placed at any position on a 3D CAD model (solids, surfaces and STL mesh models), and interactively aligned. Direction vectors define the exact 5 axis tool orientation at critical positions (e.g. severe undercuts), with the tool orientation interpolating between multiple vectors. This gives the user 100% control over the exact orientation and movement of the tool, and helps to minimize retraction movements on complex geometric topologies.

This ability of the Pictures by PC CAD/CAM software also offers a clear advantage over CAM systems that are required to calculate the 5 axis simultaneous toolpaths automatically. Due to the sheer number of possible tool orientations along a toolpath, automatic 5 axis toolpath calculation times generally take a lot longer compared to when using the Interactive Direction Vectors within Pictures by PC. In addition, the user has increased control over the resulting toolpaths.

Pictures by PC also enables the automatic positioning of vectors along guide curves at specified intervals and angles. This method lends itself perfectly to the 5 axis cutting / trimming of components (e.g. vacuum formed parts), whereby the tool has to cut around the part through multiple direction vectors. The software also includes 5 axis collision detection (tool, holder, clamps, spindle, table etc.).

Originally launched in 1984, Pictures by PC maintains a product continuity of over 35 years. SCHOTT SYSTEME GmbH continues to offer free software support without maintenance costs.

Video Presentation: 5 Axis Interactive Direction Vectors <click here>