SCHOTT SYSTEME - Design and Machining with CAD/CAM Software Pictures by PC

German software developer SCHOTT SYSTEME GmbH have released the latest version of their CAD/CAM software Pictures by PC.

German software developer SCHOTT SYSTEME GmbH have released the latest version of their CAD/CAM software Pictures by PC.

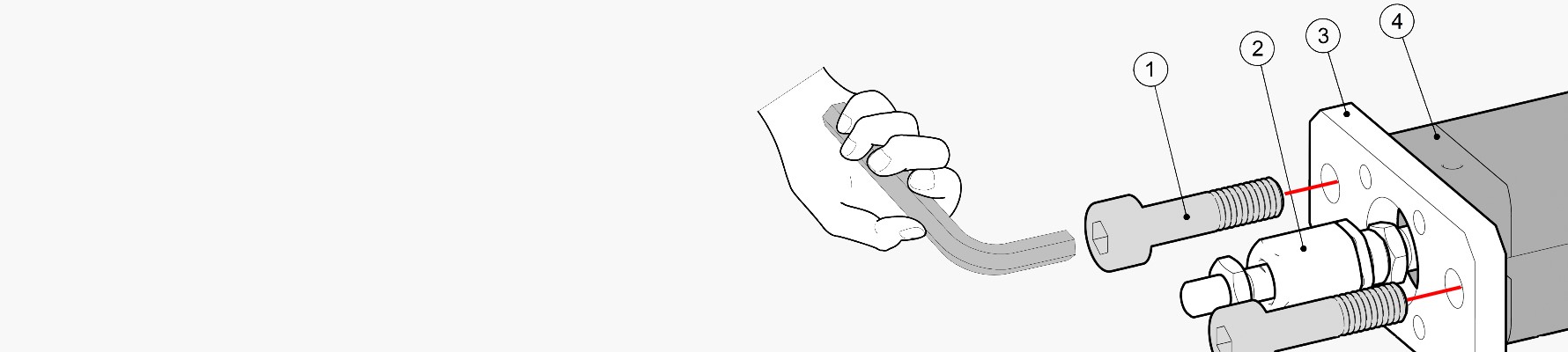

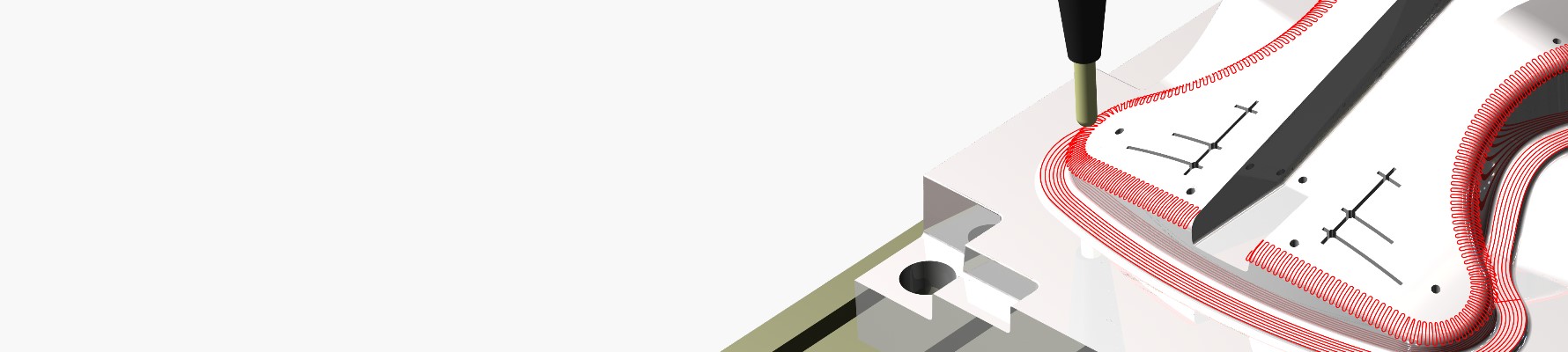

Mould designers are firstly helped by the automatic splitting of parts at edges and silhouettes curves, enabling both the core and cavity surfaces of a form to be separated from one another. The existing solid, surface and mesh Hybrid Modeller within Pictures by PC has also been extended to support mesh offsetting, ideal for the creation of wall thicknesses on imported scanned STL mesh models.

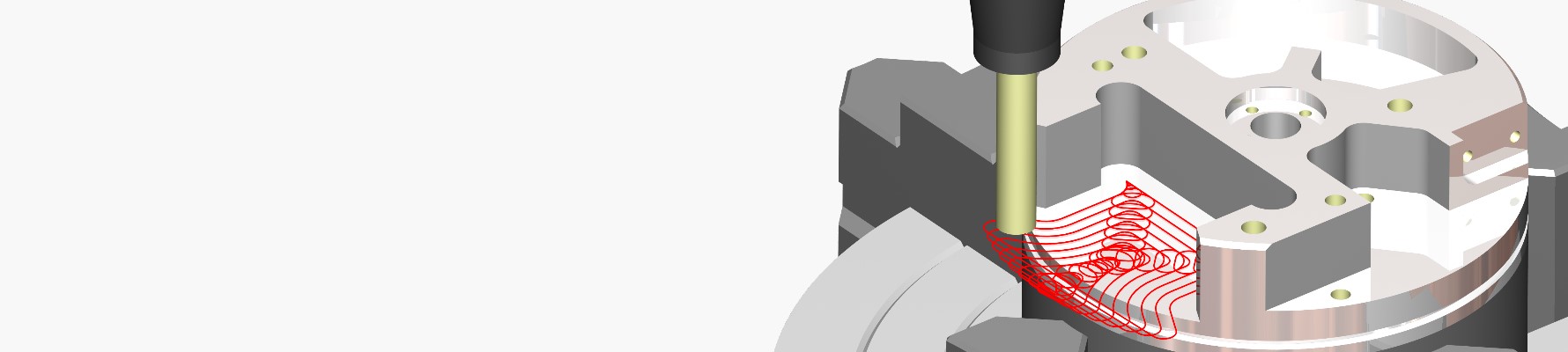

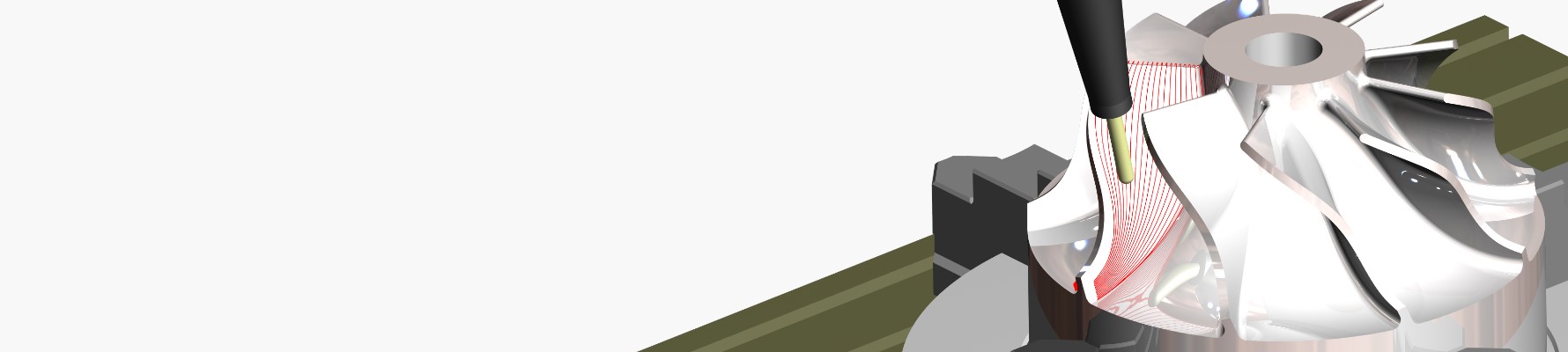

HPC (High Performance Cutting) Trochoidal 3D Roughing is implemented to facilitate the dynamic and quick removal of harder materials. 3D Spiral Finishing enables the machining of steep and flat regions of a part, with a single toolpath that adjusts to maintain a maximum stepover relating the angle of the surface to machine. Additional improvements include 5 Axis Rotary Roughing and 4 Axis Spiral Finishing operations to reduce the programming and machining times on components that require milling from multiple directions.

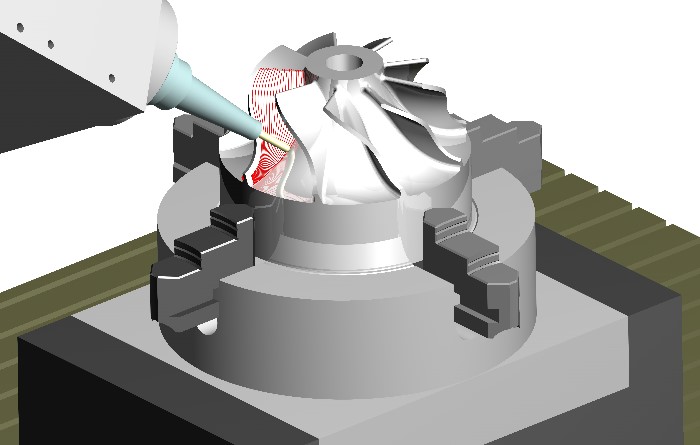

The inclusion of a new 5 Axis Simulation also helps to ensure that possible collisions between the component, machine spindle, tool and holder, clamps and the machine table are highlighted, without the need for a full machine simulation.

All of the improvements complement SCHOTT SYSTEME’s existing range of milling, engraving, wire cutting and turning tools. This software includes free of charge support and standard machine post processors, without yearly maintenance costs.

Visit SCHOTT SYSTEME GmbH at the AMB 2018 - 18th to 22nd of September - Hall 2, Stand 2A01 - http://www.schott-systeme.com