SCHOTT SYSTEME Support Multi-Axis Turn-Milling

German software manufacturer SCHOTT SYSTEME GmbH offer support for combined multi-axis turn-milling within their Pictures by PC CAD/CAM software.

German software manufacturer SCHOTT SYSTEME GmbH offer support for combined multi-axis turn-milling within their Pictures by PC CAD/CAM software.

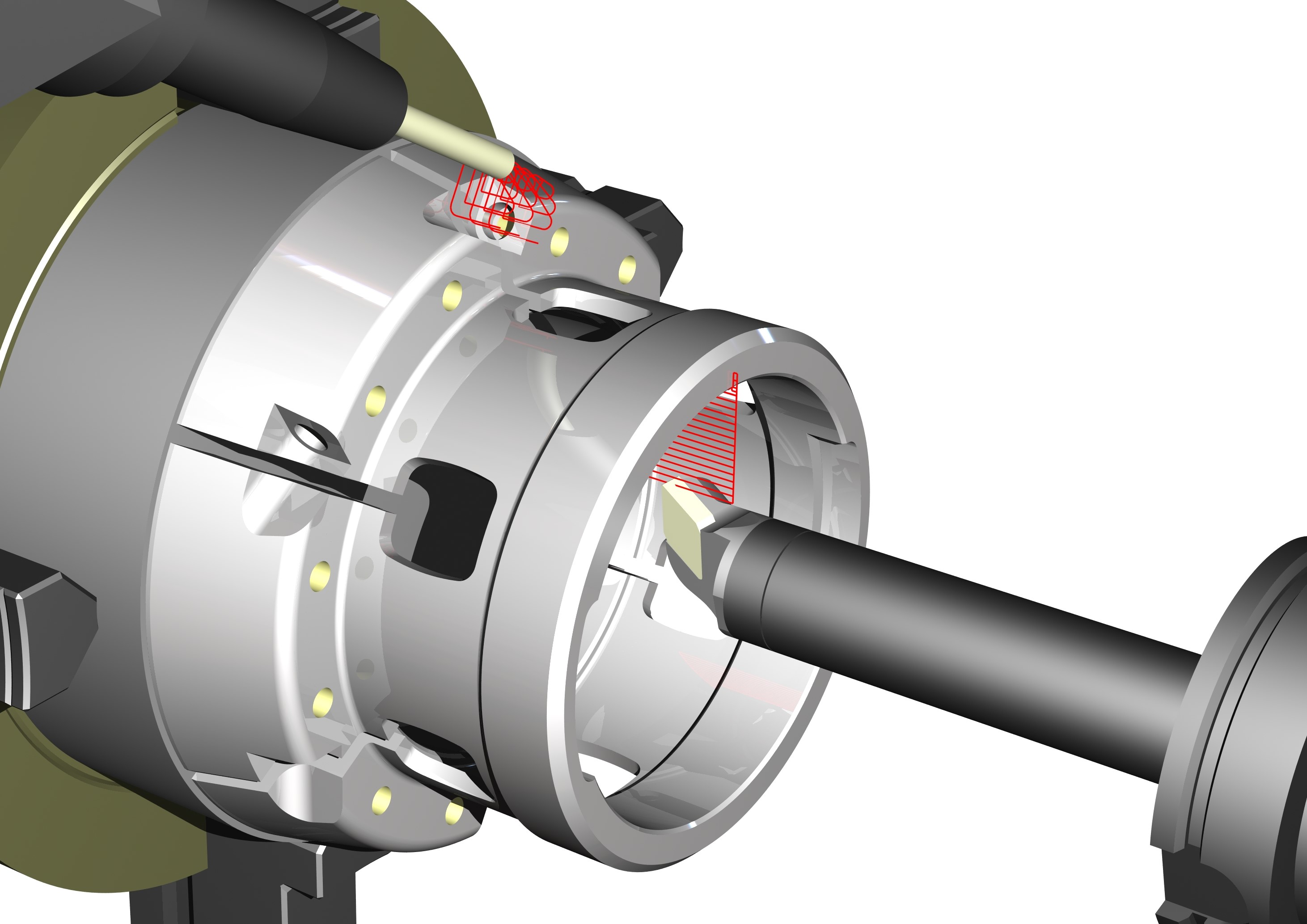

Multi-axis turn-mill (C, Y and B axes) machines facilitate the machining of complex components using a single setup, and Pictures by PC offers a single working environment for fully integrated part design and machining.

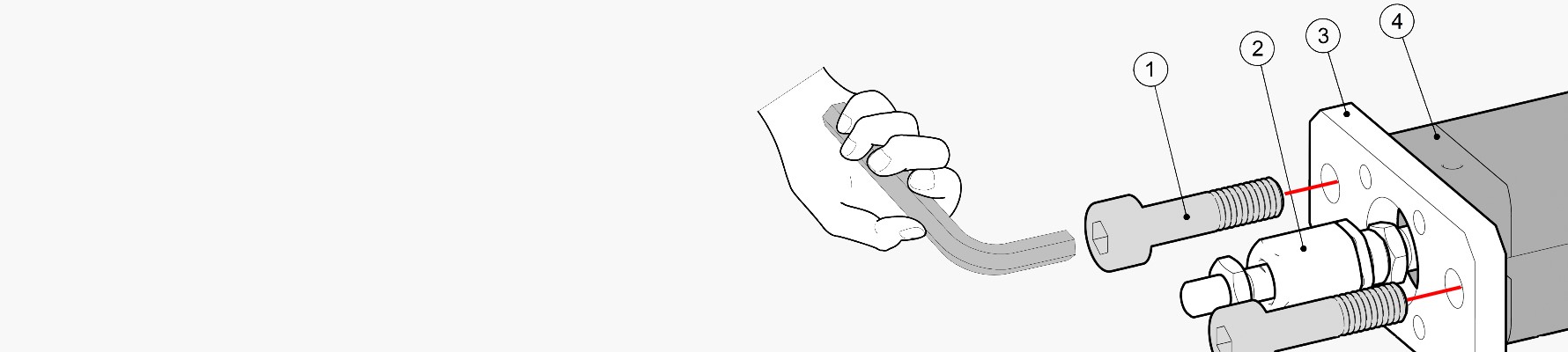

The CAD module within Pictures by PC enables the 2D / 3D construction (solids, surfaces, meshes) of any type of work piece. Turning focussed CAD functions facilitate the creation of features such as thread undercuts (DIN 76 and DIN 509) and center bores (DIN 332).

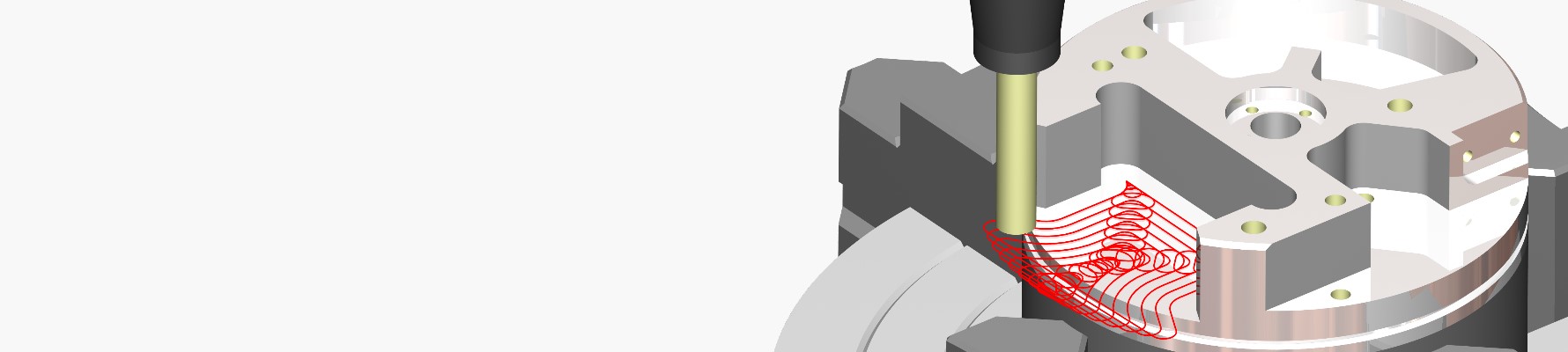

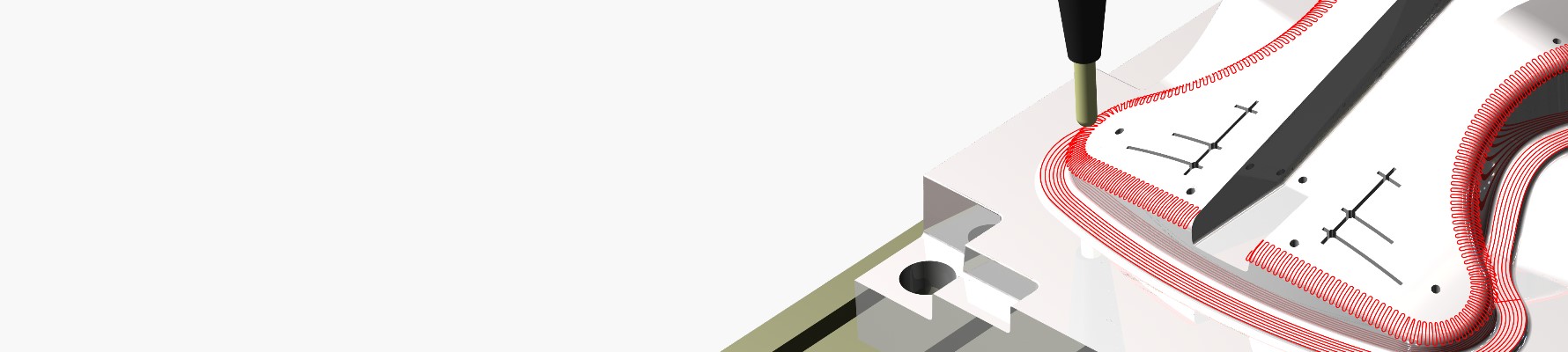

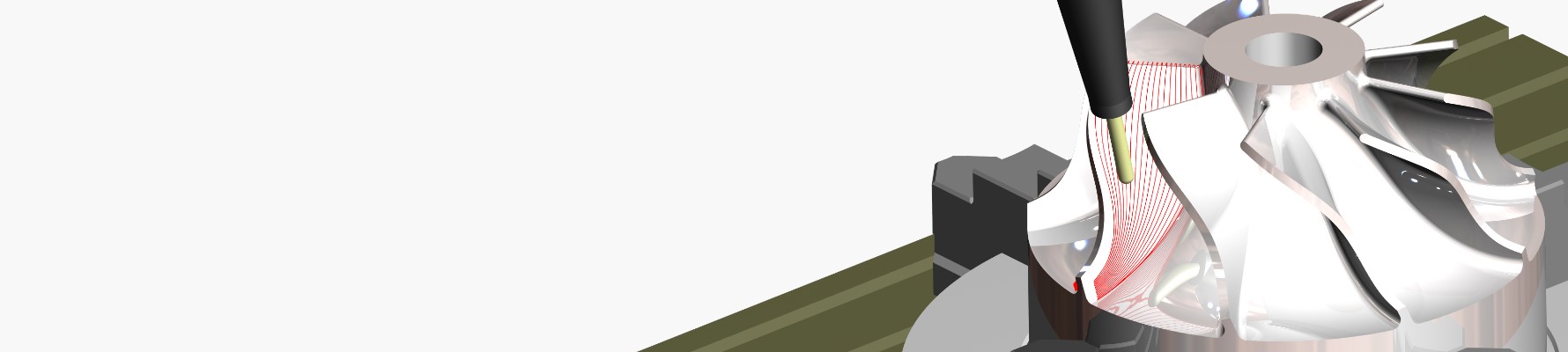

Advanced Feature Recognition tools help to analyse and identify typical prismatic milling and turning features (turning contours, pockets, holes) on both Pictures by PC and imported CAD geometry (STEP, IGES, SAT). More complex geometric surfaces can also be easily identified for the machining of free-form components (e.g., Impeller Blades).

The entire spectrum of machining strategies from SCHOTT SYSTEME (drilling, turning, 2D / 3D and 5-axis simultaneous milling) are developed in-house and utilise an identical user interface. Each machining operation can be tweaked by the customer to suit their machine, materials and preferred machining methods, and saved as a ‘CAM Sequence’ for instant application on new components. Multiple operations (e.g., face turning, roughing, rest material and finish turning) can also be saved as a single CAM sequence in order to drastically reduce the programming times for complex parts. The entire range of innovative 3D and 5-axis free-form surface milling strategies makes Pictures by PC an ideal solution for machining the most complex of turn-mill components.

The range of variance of multi-axis turn-mill machines lathes should not be underestimated, therefore post-processors are individually adapted to each machine (according to the turret and spindle configurations). SCHOTT SYSTEME GmbH customers also receive free support directly from the software manufacturer.

Originally launched in 1984, Pictures by PC maintains a product continuity of over 35 years. SCHOTT SYSTEME GmbH continues to offer free software support without maintenance costs.

Video Presentation: Multi-axis Turn Milling <click here>