Pictures by PC Version 3.10 - Highlights

Version 3.10, the next generation of the CAD/CAM software solution Pictures by PC from SCHOTT SYSTEME GmbH, is available. Based on almost 40 years of continuous development experience, the new release 3.10 once again achieves increasing productivity gains for design and manufacturing.

Automated Milling

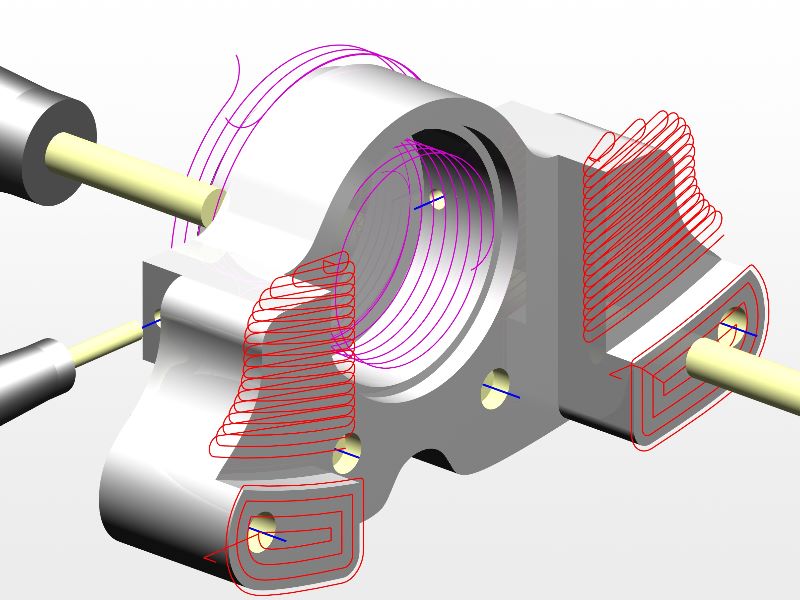

Small batch sizes, increasing cost pressures and staff shortages nowadays require a higher degree of automation of classical CNC processes. The new software release from SCHOTT SYSTEME GmbH focusses on this with its CAMsmart technology, automating the manufacturing process for multi-sided machining of typical, prismatic workpieces.

The process begins with the construction or import of the 3D CAD volume model (usually via STEP or IGES, VEC and VCZ). The part, which may come supplied in any number of different orientations, is then aligned ready for production. This is followed by the geometric analysis of the workpiece, in which typical, multi-sided 2.5D or 3D milling and drilling features are identified. Appropriate CAM strategies are then assigned to these so that the part can then be manufactured on the machine (e.g., facing, contouring, pocket milling, chamfering, drilling, edge rounding). All of the above-mentioned steps run automatically, but can be modified or supplemented at any time by experienced users.

Use of New Tool Forms

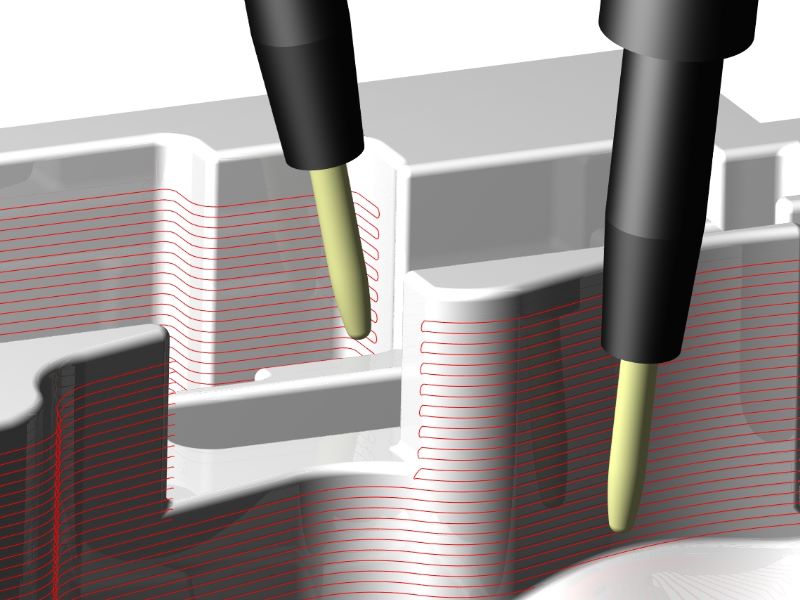

In the new 3.10 version, user-defined tool shapes (e.g. parabolic cutters, barrel cutters, concave radius cutters, etc.) can now be defined using a 2D sketch (e.g. DXF) and used on 3- to 5-axis milling machines.

For example, parabolic or multi-radius milling cutters considerably improve the machining of steep and flat areas, as the larger radii curvature of the milling cutter facilitates larger tool path stepover distances compared to conventional spherical or torus milling cutters, while maintaining the same surface roughness. This leads to a reduction in the number of tool paths, a reduction in machining time and an increase in tool life while maintaining the same surface quality.

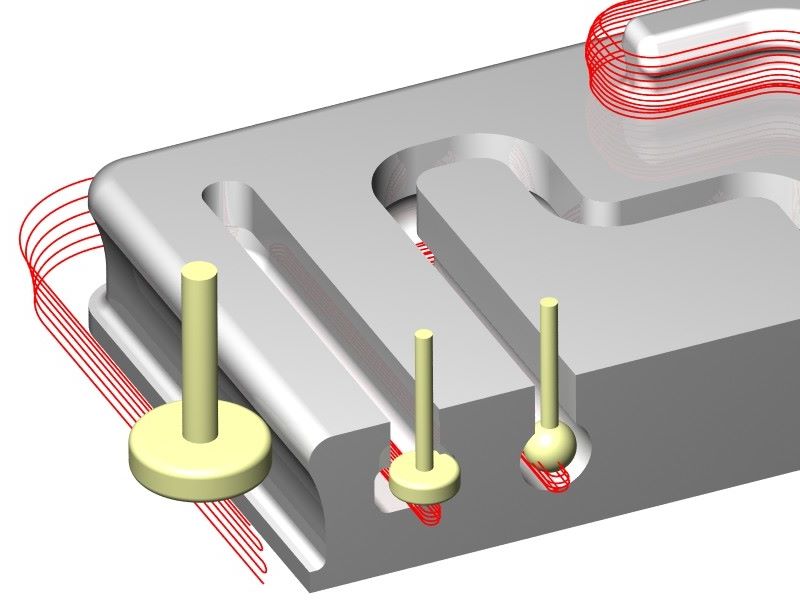

Enhanced Machining of Plate Material

In the case of components in sheet material, in order to keep the parts in position when machining, the milling contours now include tags, which can then be separated with a second operation using a number of differing methods. The user has full control over the tag position (manual or automatic placement), length and height etc., as well as the removal method. The machining of contours has also been significantly enhanced, e.g. with more complex approach and milling methods.