Innovation in Mould Making with Pictures by PC CAD/CAM Version 3.10 - Moulding EXPO 2023

At the Moulding EXPO (Stuttgart, June 13-16, 2023), the German software manufacturer SCHOTT SYSTEME GmbH will demonstrate the significant performance enhancements of version 3.10 of its Pictures by PC-CAD/CAM software, with special focus on mould and model making.

At the Moulding EXPO (Stuttgart, June 13-16, 2023), the German software manufacturer SCHOTT SYSTEME GmbH will demonstrate the significant performance enhancements of version 3.10 of its Pictures by PC-CAD/CAM software, with special focus on mould and model making.

The proven 3D hybrid modeler (volume, surface and mesh) from Pictures by PC has been offering a comprehensive software package for design, construction and free-form design for almost 40 years. The new version 3.10 is equipped with the latest modelling kernel, which guarantees significant performance improvements in almost all modelling functions. Noteworthy new features include the faster generation of 2D detail drawings from large 3D assemblies and the new wall thickness analysis with colour gradient display. Significant advancements in feature recognition and local operations for model modification are also included, both of which greatly help the CAM machining.

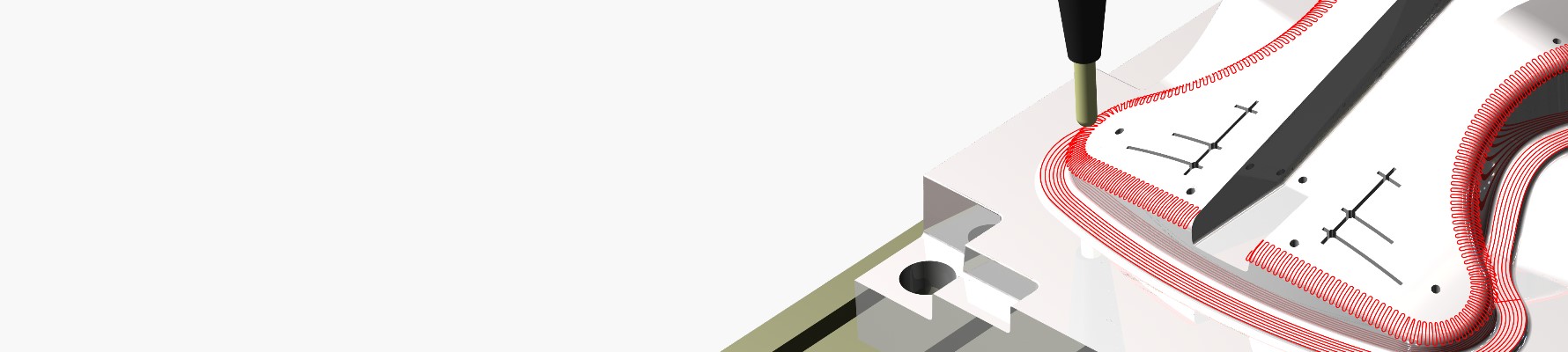

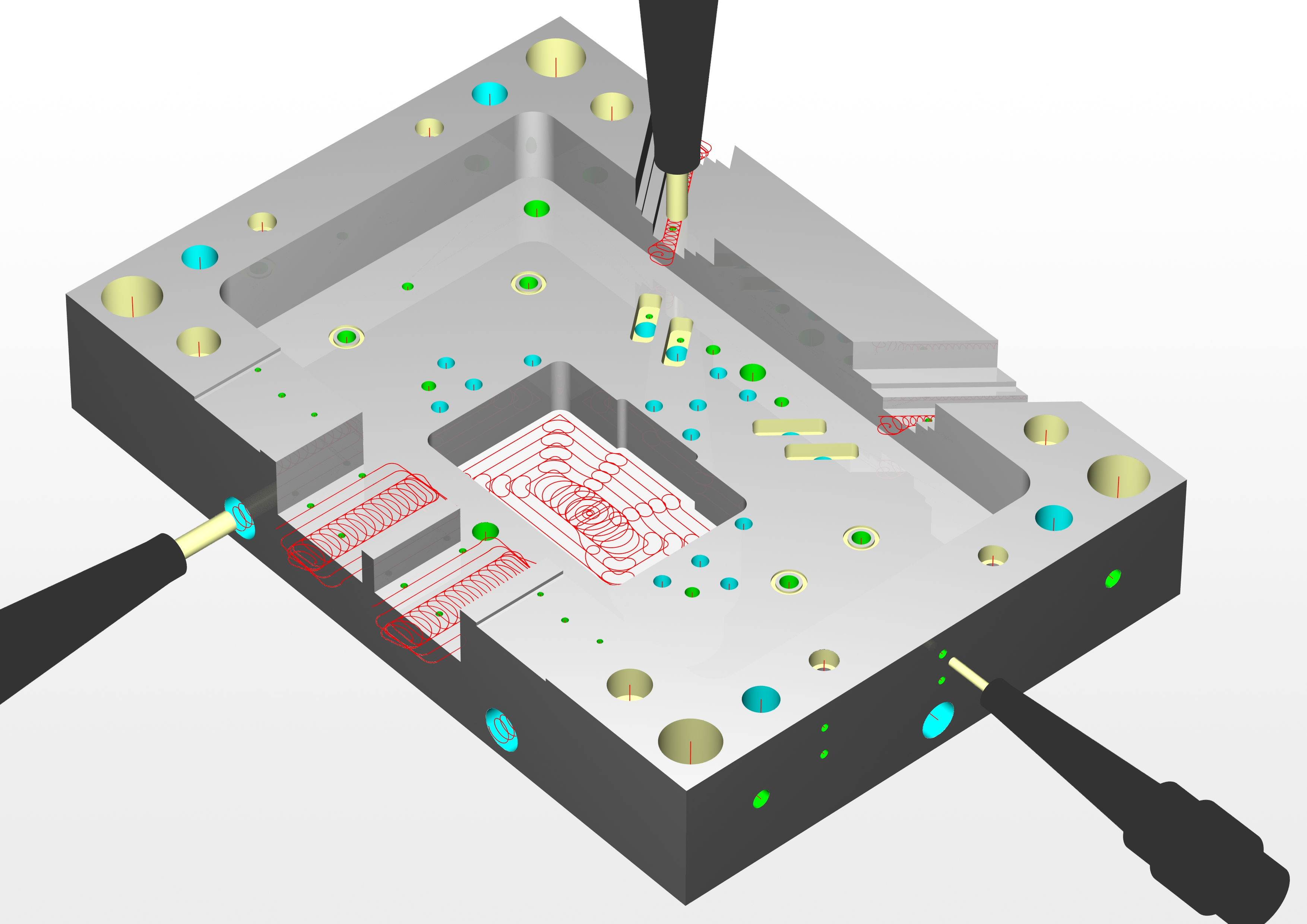

The brand-new automated milling CAMSmart is a particular focal point of Release 3.10. This drastically reduces the CAM preparation times (at least by a factor of 10) of typical multi-sided, prismatic workpieces (mold bases and fixtures) compared to previous procedures.

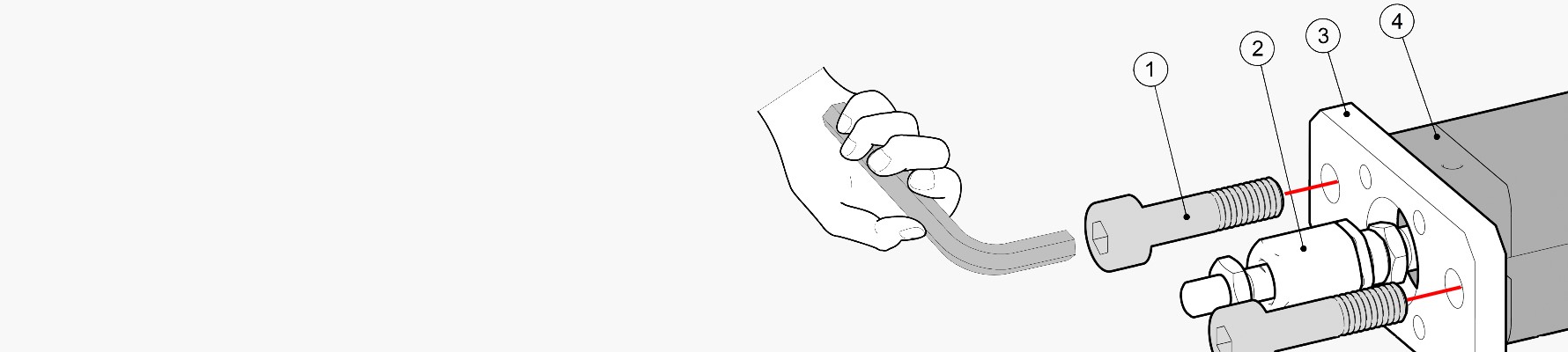

The component geometry is analyzed for typical, multi-sided 2.5D or 3D milling and drilling features on constructed or imported 3D CAD volume models (usually via STEP, SAT, IGES or VEC and VCZ). The processing of the workpiece is then automatically prepared according to the part criteria, e.g., according to material, pocket size, corner radii and drill hole types (e.g. facing, contouring, pocket milling, chamfering, drilling, edge rounding). Despite the automation, this work sequence is completely transparent for the user and can be modified at any time.

This automated process naturally includes a visual inspection (material removal or path simulation) as well as a rest material and collision analysis.

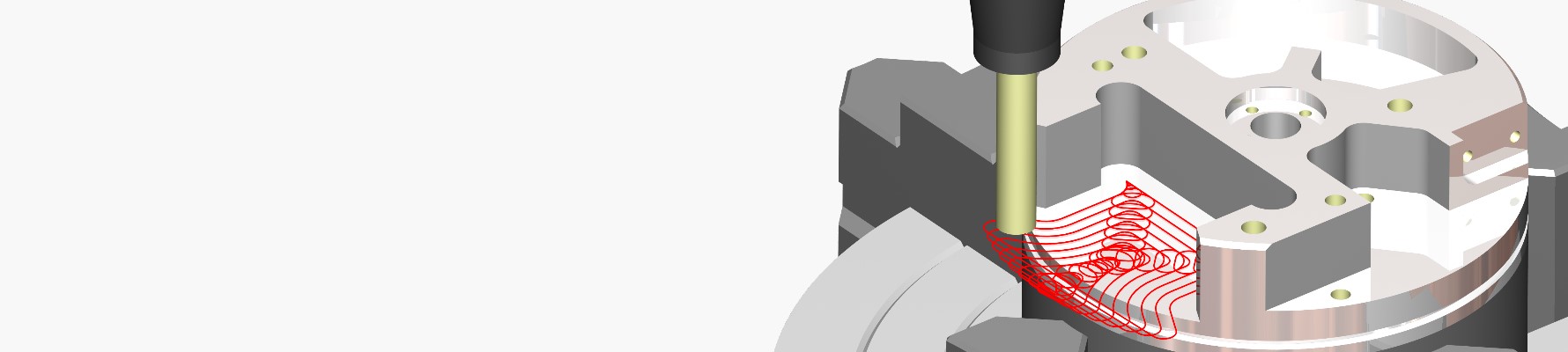

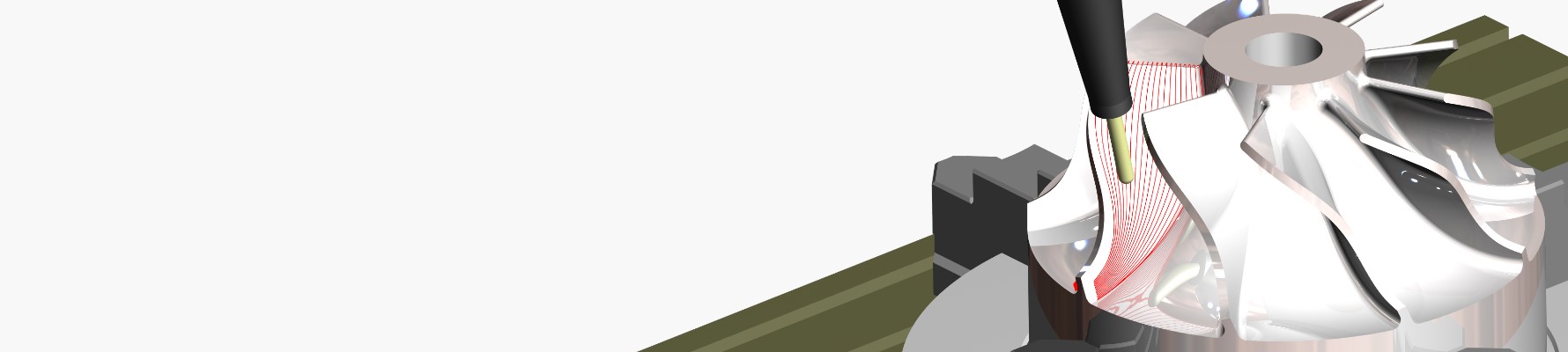

Version 3.10 of Pictures by PC has also been significantly expanded in the area of the 3D machining of free-form components (form tools, model making). Custom tool shapes (e.g., parabolic cutters, barrel cutters, concave radius cutters) definable by a 2D sketch (e.g., DXF) can now be used with 3- and 5-axis milling strategies. The machining of complex undercuts with lollipop and T-slot milling cutters is also supported.

The 5-axis trimming of thermoformed components now also includes the option of locally changing the cutting depth and offset allowance at different points on the contour. This is ideal for components with different material thicknesses.

With its self-developed software solutions, SCHOTT SYSTEME GmbH can look back on almost 40 years of product continuity. To date, no maintenance or support costs are be charged for the software. All standard machine postprocessors are included within the standard solution.

The proven SCHOTT SYSTEME motto applies: Software benefits instead of software costs.

Moulding Expo 2023 - Hall 1 Stand 1D64

www.schott-systeme.de